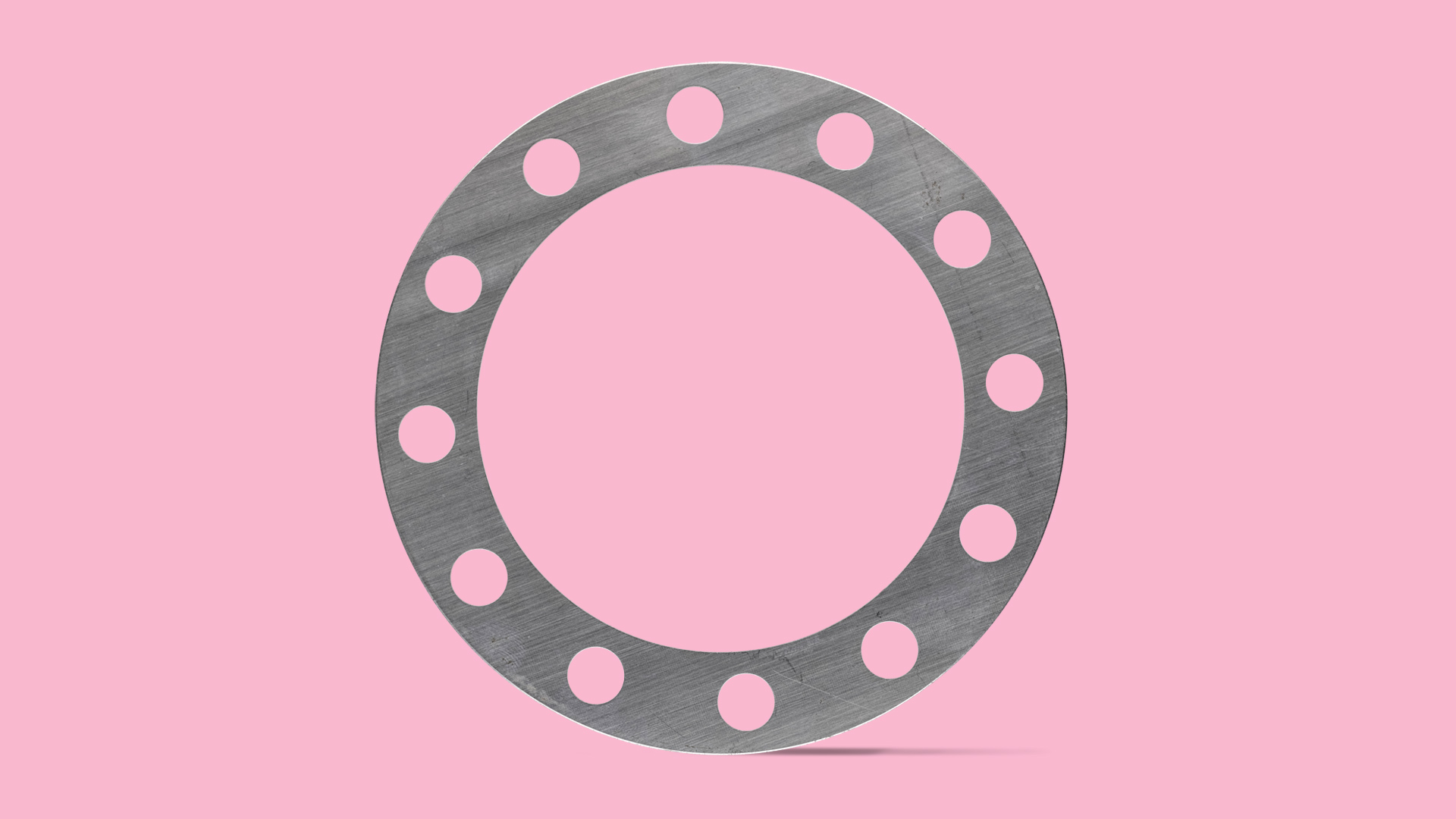

CNC milling of aluminum

Do you need reliable and precise CNC milling of aluminum? At Thor Ahlgren, we combine decades of craftsmanship with modern technology to create customized solutions that meet your specific needs. We work with both small companies and large industrial groups, giving us the experience and flexibility to handle a variety of metalworking challenges.

How we mill

Milling up to size x=1016 Y=508 Z=635

Contact us

Contact us and we will help you

Extensive experience in industry

With our extensive experience of working with bilindustry, we have developed a deep understanding of industry's specific requirements and needs. We work closely with manufacturers and suppliers in bilindustry to deliver aluminum parts with the highest precision and quality. Our solutions cover everything from prototyping to series production, helping bilindustry to achieve its goals of sustainability, lightweight and cost-efficiency.

Tips for efficient CNC milling of aluminum

Milling aluminum requires a careful approach to ensure both precision and quality. Here are some simple tips to improve your work with aluminum:

Choice of milling tools and cutting geometry

- Sharp tools at the right angle: Use tools with sharp cutting edges and a positive rake angle (γ) between 10° and 20°. This reduces cutting pressure and prevents aluminum from sticking to the tool.

- Polished cutting edges: Tools with polished cutting edges reduce friction and provide better surface quality.

Optimal cutting speed and feed rate

Cutting speed (Vc):

An ideal cutting speed is between 400-800 m/min, depending on the aluminum alloy and tool material.

Formula for spindle speed (n):

n = (1000 × Vc) / (π × D)

There:

- n = spindle speed (rpm)

- Vc = cutting speed (m/min)

- D = tool diameter (mm)

Feed rate (Vf):

Calculate the feed rate to achieve optimal processing.Formula for feed rate:

Vf = fz × z × n

There:

- Vf = feed rate (mm/min)

- fz = feed per tooth (mm/tooth), recommended 0.1-0.3 mm/tooth for aluminum

- z = number of teeth on the tool

- n = spindle speed (rpm)

Cooling and lubrication

- Prevent overheating: Use high-viscosity coolants that effectively cool and lubricate during processing.

- High pressure cooling: This helps to remove chips quickly and prevents the material from sticking.

Chip control and chip flow

- Keep the work area clean: Use high pressure blowing (at least 6-8 bar) with air or coolant to remove chips.

- Reduce scratches: By effectively removing chips, you reduce the risk of scratching the workpiece.

By following these simple tips and adjusting your machining parameters, you can ensure that milling aluminum is efficient and produces a high-quality end result.

Modern technology meets traditional craftsmanship

Thor Ahlgren is built on a heritage of metalworking that spans several generations. Our technicians are trained in traditional crafts while working with our CNC milling machines. This combination of experience and technological innovation makes us unique. Our milling machines ensure an optimal balance between precise tolerances and high surface finish - every time.

CNC milling of aluminum

Aluminum is a common material for CNC milling due to its lightness, strength and machinability. At Thor Ahlgren, we work with milling of aluminum to meet different needs. We strive to deliver aluminum parts that meet high quality and tolerance criteria.

Contact us for more information

Looking for a reliable partner for CNC milling of aluminum? Contact us today to discuss how we can help you. With Thor Ahlgren, you get a partner that combines precision, tradition and sustainability in every project. We look forward to contributing to your success.

Thor Ahlgren - Your partner in advanced CNC milling.