Fine blanking

Fine or blind die-cutting, do you know the difference?

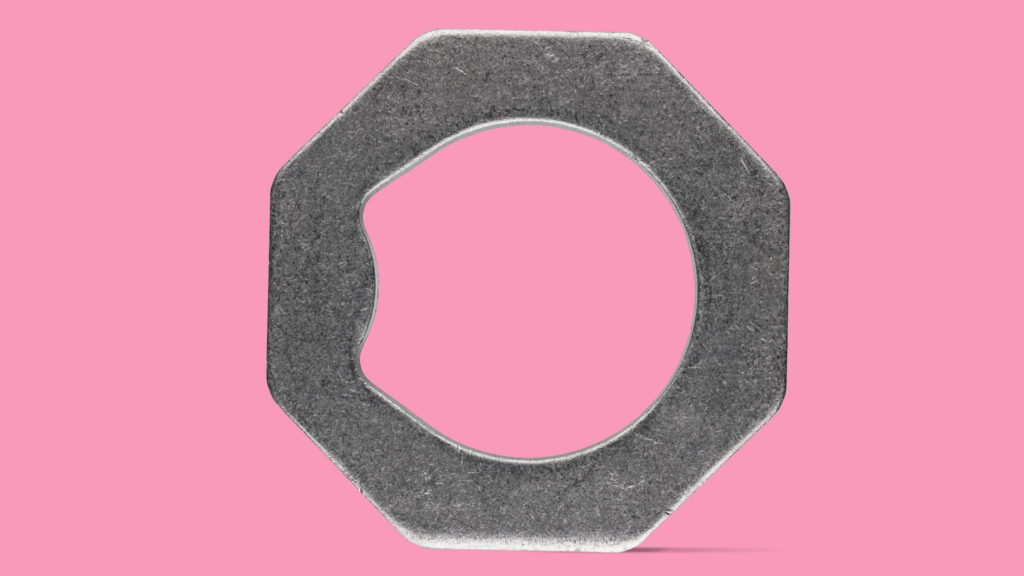

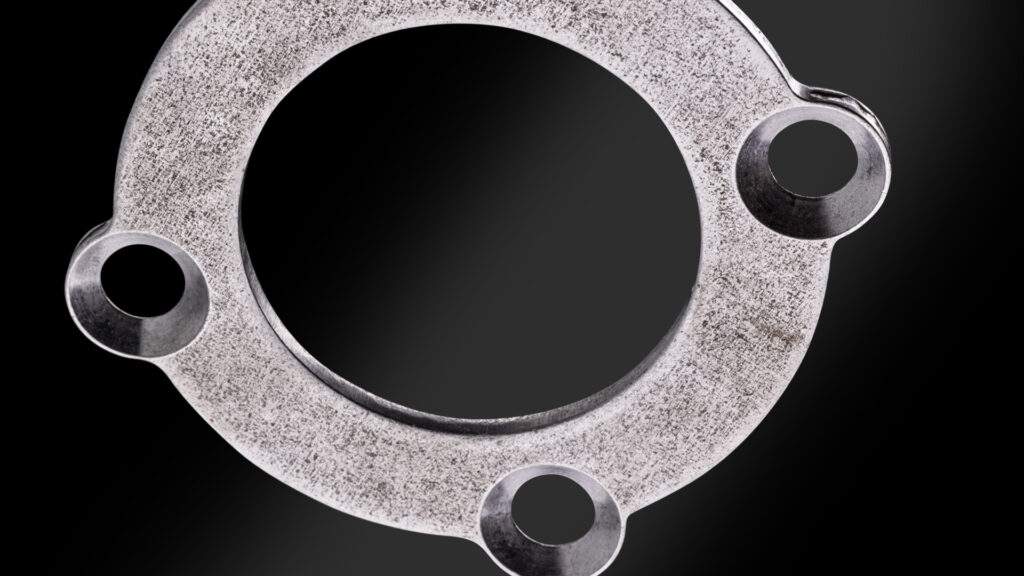

Fine blanking of products with functional area requirements and tight tolerances.

Product characteristics fine blanking

High demands on tolerances, surfaces and flatness

High demands on functional spaces

Thickness up to 10mm

A long history of experience

We have always been proud of our experience and commitment to quality. With fine blanking, we continue to build on our long tradition in metalworking, while usinghe advanced fatigueto meet today's demands for precision and efficiency. Our specialists, who have worked in the industry for decades, combine their know-how with the latest technology to ensure accurate and sustainable results in every project.

What is fine blanking?

Fine blanking is a precision machining method in sheet metal working where sheets are formed and punched with high accuracy. The technique uses special punching tools that cut the material with minimal deformation, resulting in smooth and sharp edges. Fine blanking enables the production of complex parts with tight tolerances and is widely used in industries such as automotive, electronics and medical technology where high quality and precise fit are required. The method is effective for producing large volumes of parts with complex geometries

Unlike traditional punching where cut surfaces can be rough, fine blanking offers a superior surface finish and higher accuracy.

Sustainability and choice of materials

Our work is not only based on skilled craftsmanship and modern technology. We also have a strong focus on sustainability. Thor Ahlgren works with a wide range of materials, from stainless steel to aluminum and other alloys, enabling us to manufacture products for different industries and applications. We prioritize sustainable material choices and optimize our processes to reduce environmental impact.

Advantages of fine blanking

Fine blanking offers several advantages over other blanking methods. Some of these are:

- High precision and tight tolerances

- Ability to produce complex geometries

- Smooth and clean cut surface without the need for post-processing

- Efficient production at high volumes

These advantages make fine blanking a cost-effective and high-quality method for manufacturing components in demanding environments.

Contact us

If you are looking for a reliable partner for the production of detailed, high-precision metal parts, contact us at Thor Ahlgren. We offer customized solutions and can help you find the right technology for your specific needs.

Contact us and we will help you