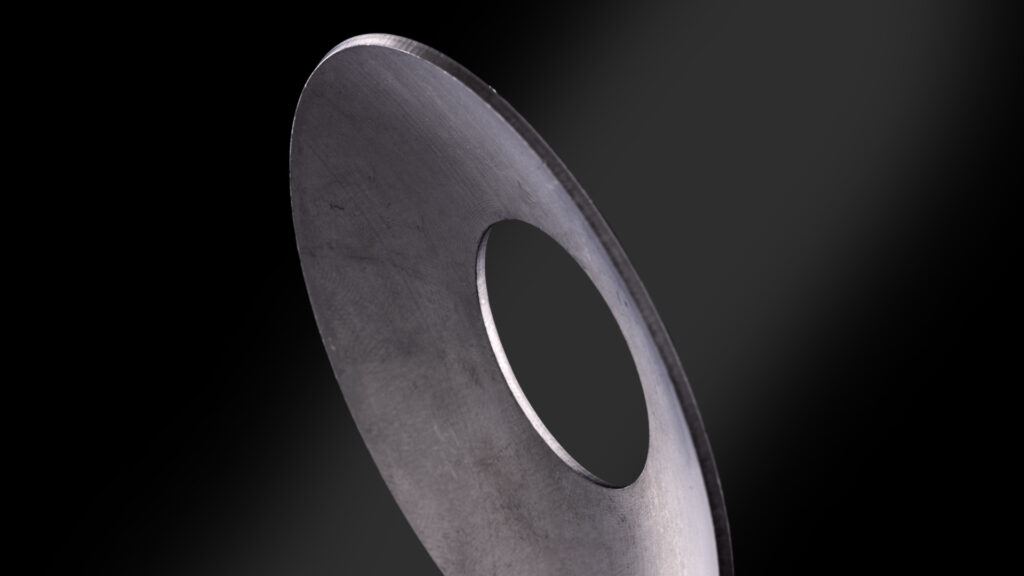

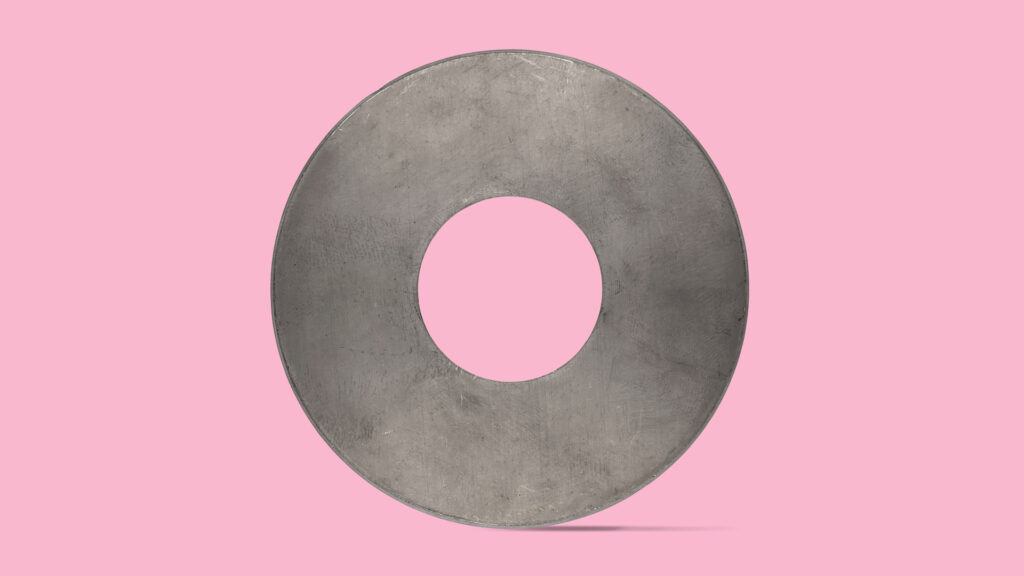

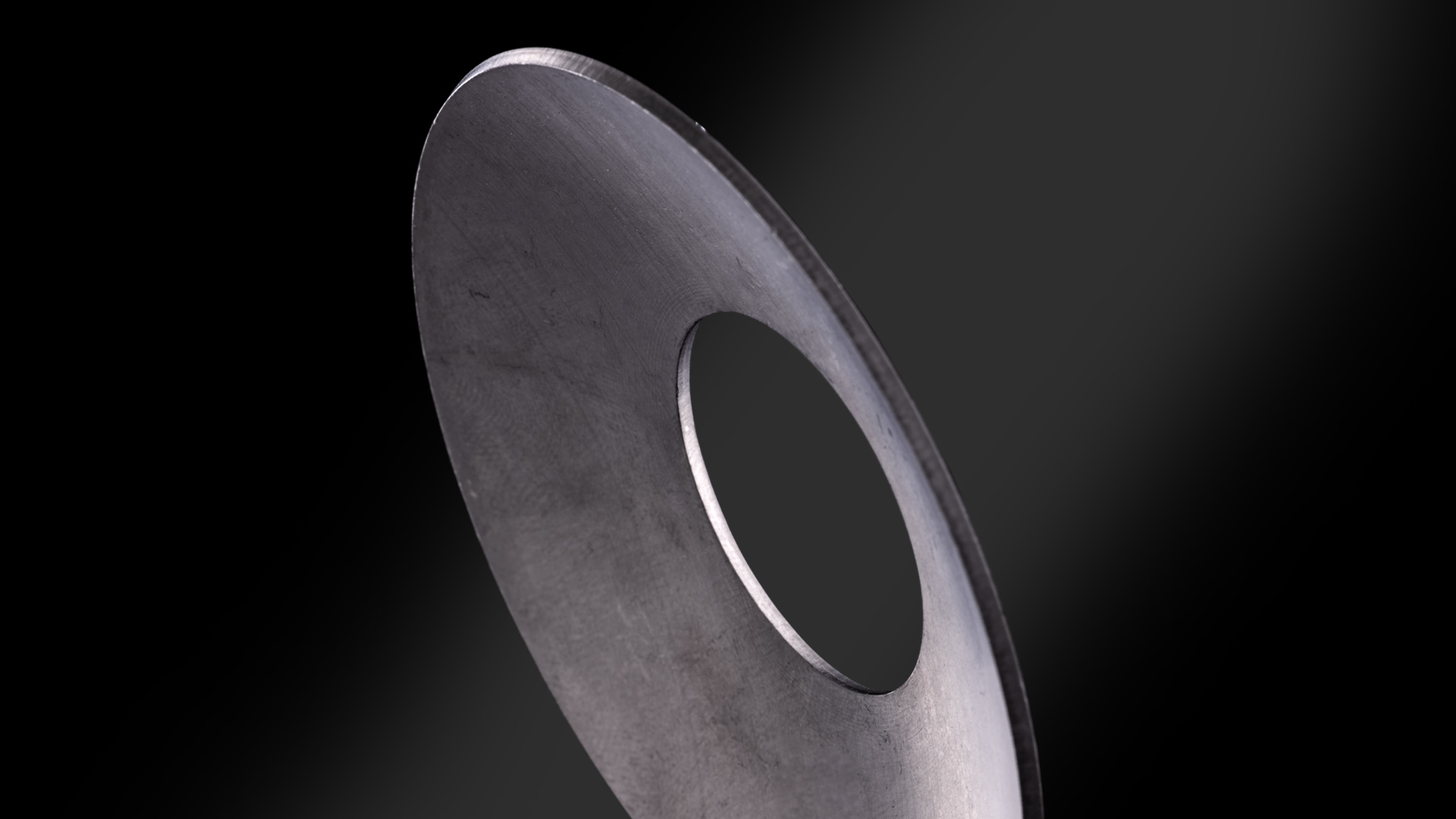

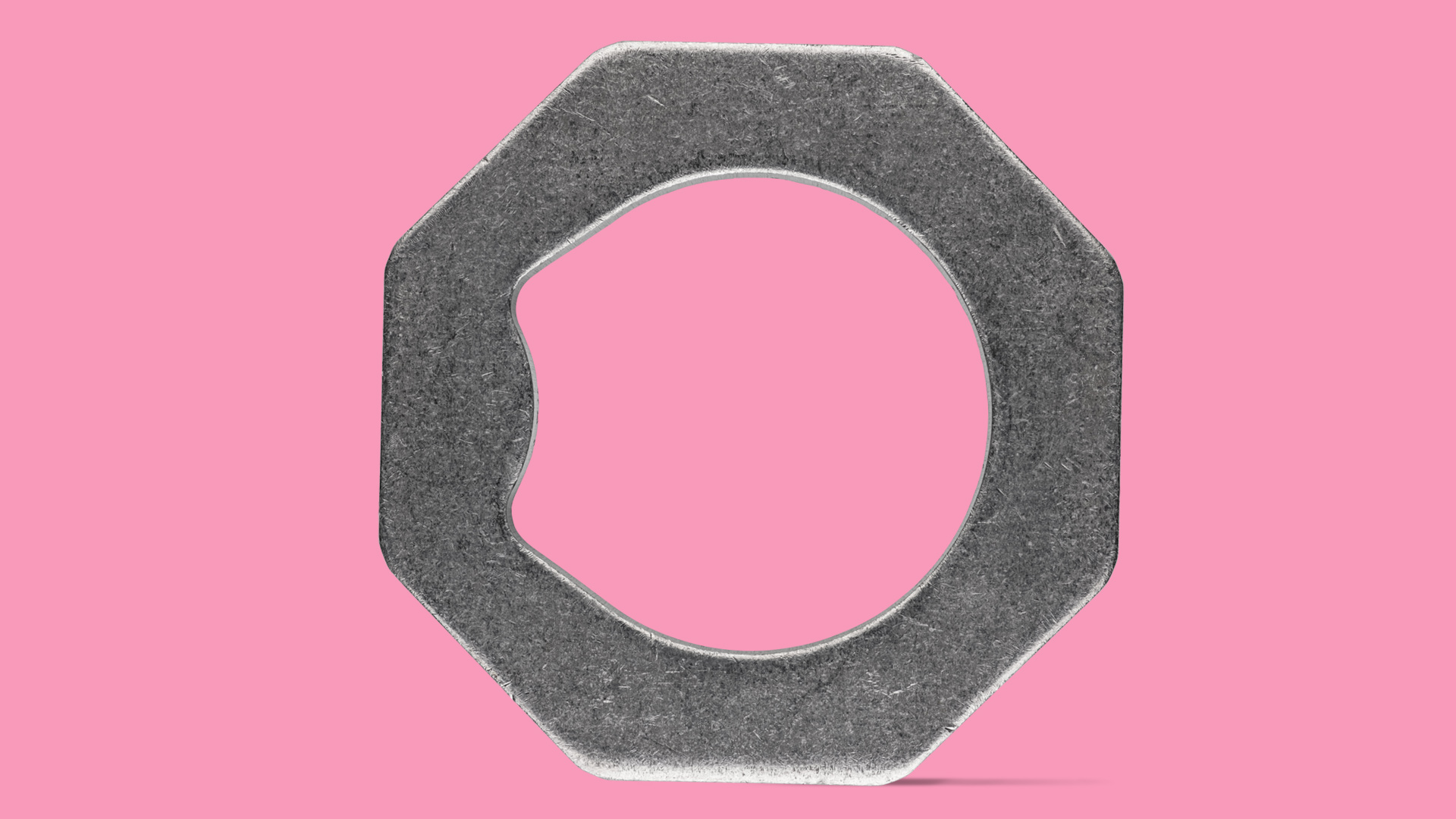

Punching of sheet metal

Sheet metal stamping is one of the most cost-effective methods of producing metal components. At Thor Ahlgren, we have worked with stamping since the early 1900s, combining our deep experience with modern technology to deliver the highest quality results.

Whether simple or complex products, we can meet your needs. Our advanced automatic presses process materials such as steel, stainless steel, aluminum, copper and brass with tolerances down to 0.10 mm and tensile strengths up to 1,500 MPa.

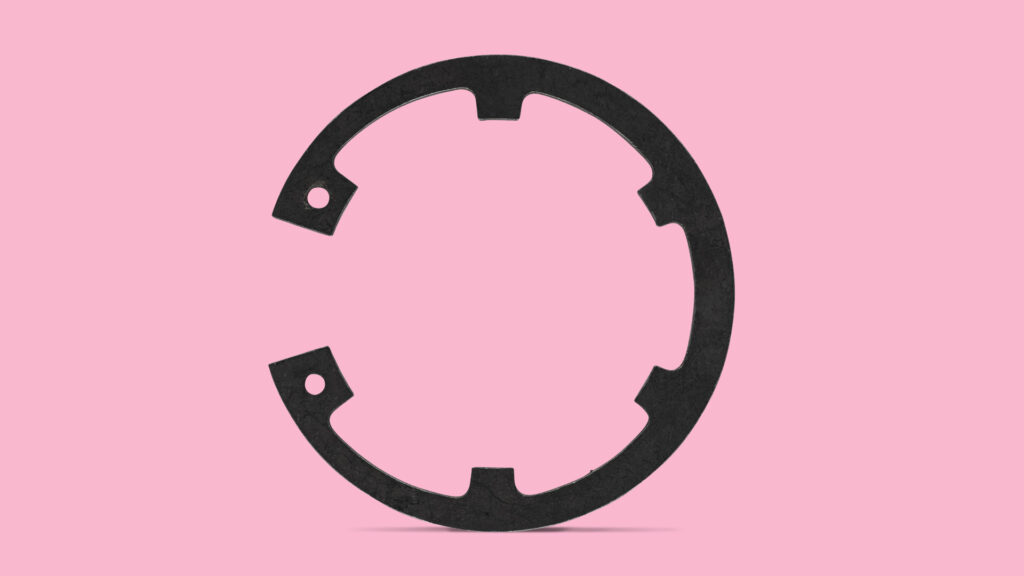

Product features punching

Made of steel, hardenable steel, stainless steel, high strength steel, copper, brass, aluminum

Thicknesses down to 0.10 mm

Up to 1 500 MPa ultimate tensile strength without subsequent hardening

High demands on flatness and tolerance

Contact us

Contact us and we will help you

Our punching services - highest precision and quality

At Thor Ahlgren, we always set the highest standards for quality and precision. Thanks to our modern machinery and our skilled employees, we can offer:

- Material variation: We process everything from brass and aluminum to high-strength steel and stainless steel.

- Tolerances and flatness: Perfect flatness and small tolerances are essential for the functionality of the components, and we guarantee results that meet these requirements.

- Thickness of material: We handle thicknesses down to 0.10 mm, giving us the flexibility to work with both thin and thick materials.

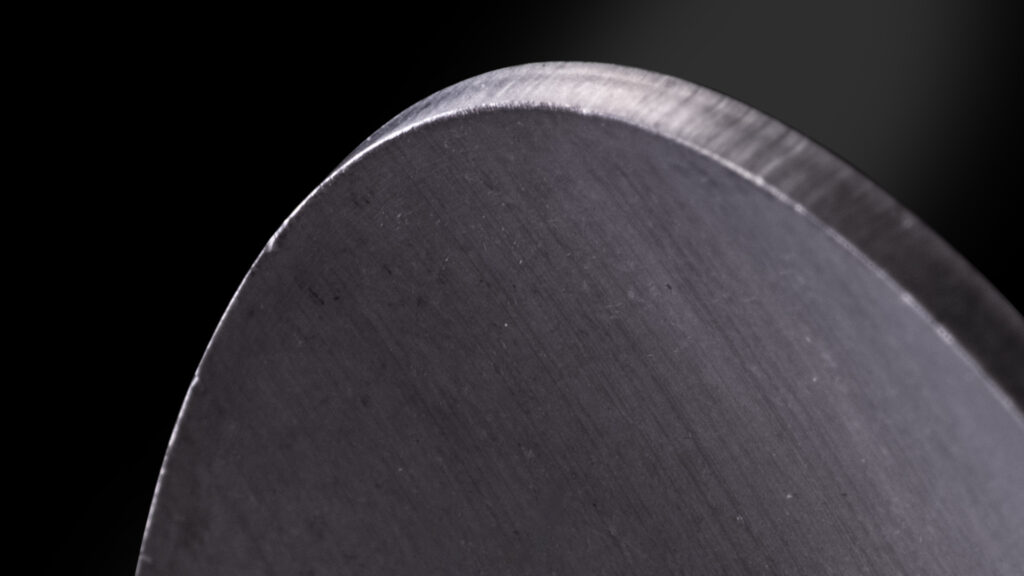

Our customers also appreciate that we can combine punching with other machining methods, such as laser cutting and CNC machining, to create complete solutions.

Why customers choose Thor Ahlgren

Since 1918, Thor Ahlgren has been a reliable partner in Swedish industry. Our journey began with in-house produced tools and machines, and today we are one of the country's most qualified contract manufacturers. More than 100 years of experience means we understand the demands of industry and can deliver solutions that work. We continuously invest in the latest equipment to stay at the forefront. In addition, we measure our CO2 footprint at item level and strive for sustainable production, which includes both environmental and social responsibility with a safe working environment for our employees. We are flexible and adapt to the needs of our customers, whether it is for small series or large-scale production.

How we work - from prototype to series

- Needs analysis & DFM. We review material selection, geometry, tolerances, surface requirements and volume to identify the best manufacturing strategy.

- Prototype. We verify function and tolerance before ramp-up.

- Serial production. Our machines and experienced operators ensure a steady pace and quality.

- Quality control. Documented measurement and final inspection before delivery.

Combine punching with laser cutting for optimal results

For customers looking for even greater versatility, we offer the option of combining punching with laser cutting. This is ideal for projects that require complex shapes or tight tolerances. This combination allows us to fulfill your needs in a way that is both cost-effective and precise.

Your partner in die-cutting

Need a reliable partner for sheet metal stamping? Thor Ahlgren has the solutions you are looking for. Contact us today for a free consultation or quote. Discover how our experience and modern technology can help you achieve your goals.