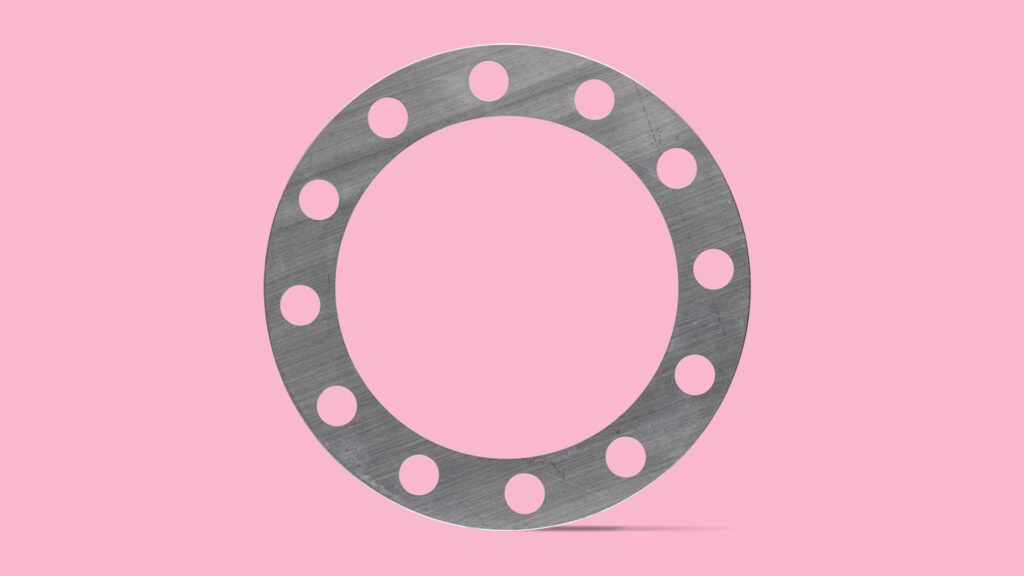

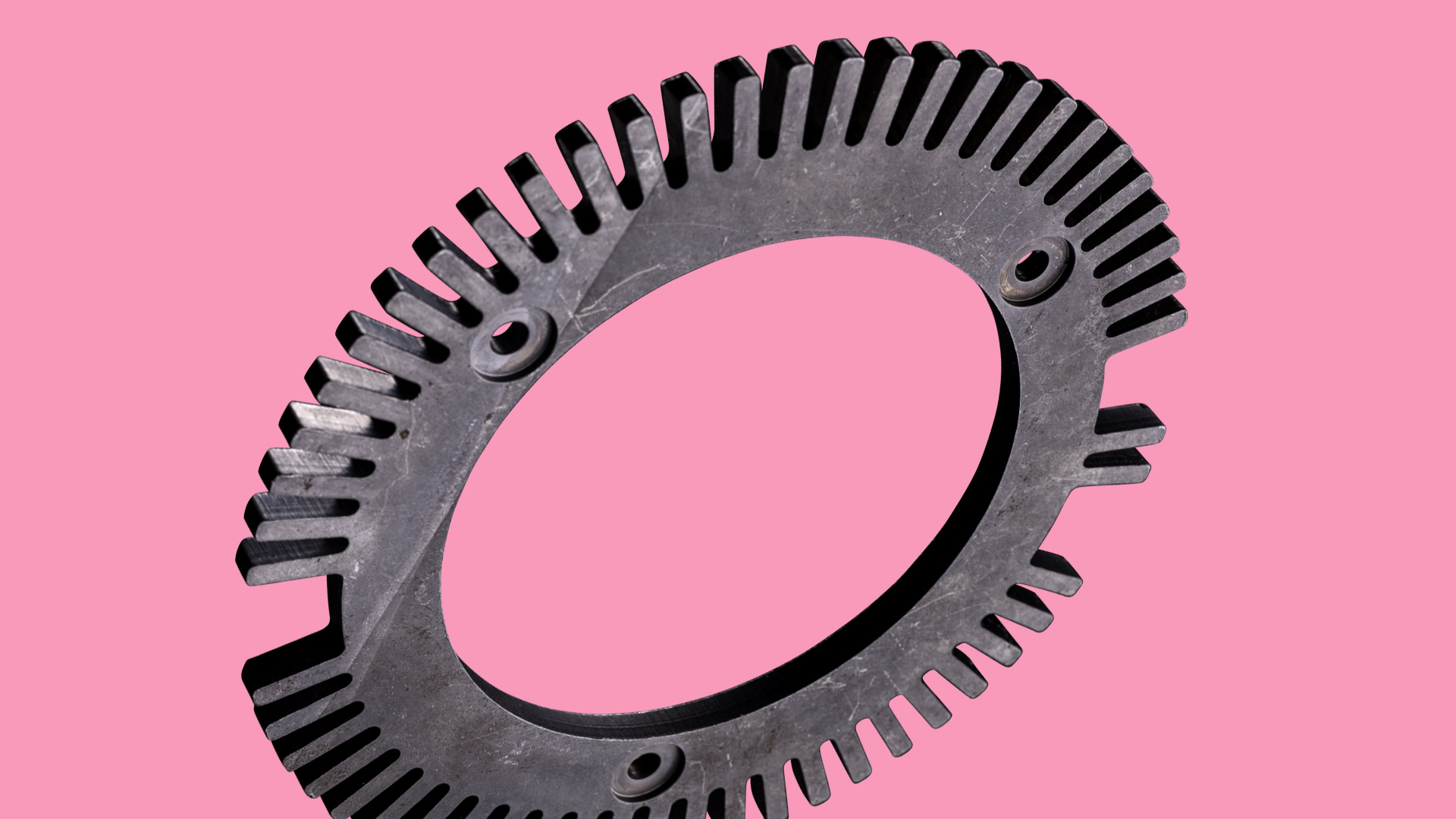

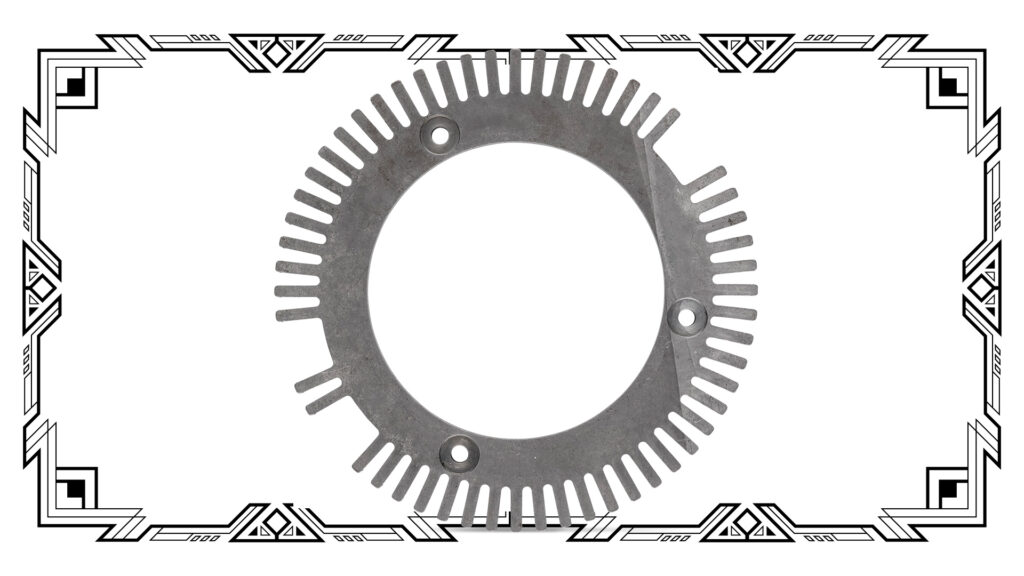

Milling of steel

From prototype to mass production, which do you prefer?

Milling steel requires precision, experience and the right technology. Whether it's machining steel or complex components for industry, choosing the right supplier is crucial. At Thor Ahlgren we have over 100 years of experience of metalworking, and we know what it takes to deliver the highest quality.

Product features milling

Materials, black plate, extra high strength steel, wear plate, heavy plate, blanks, stainless and aluminum

Milling up to size x=1016 Y=508 Z=635

Contact us

Contact us and we will help you

What is steel milling?

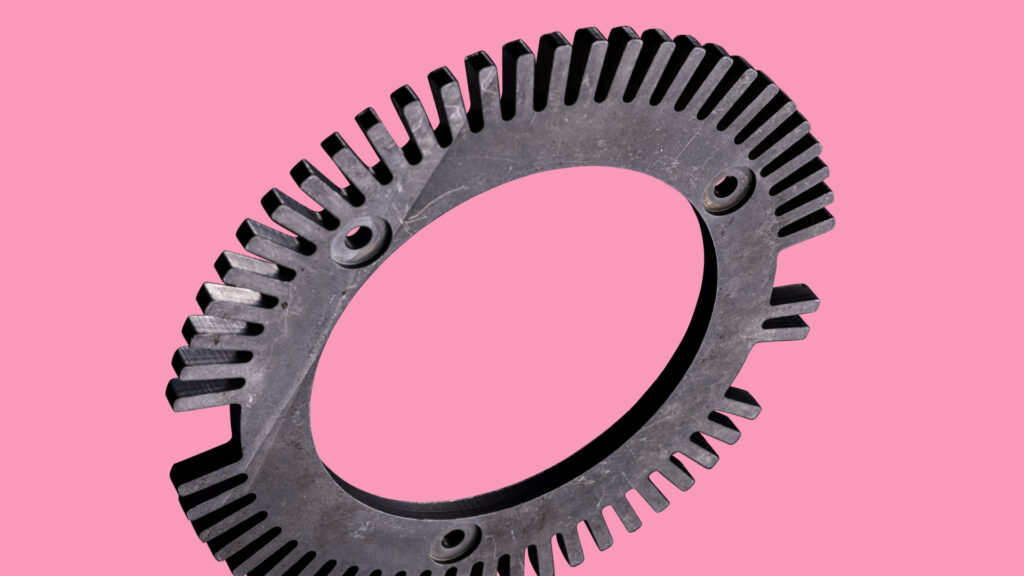

Milling is a machining method in which rotating cutting tools remove material to create high-precision parts. Steel is one of the most widely used materials in industry, but its hardness and variations in alloy place high demands on the milling method.

We work with:

- Black plate, extra high strength steel, wear plate and heavy plate

- Raw materials such as steel round bars, flat steel, square bars and stainless steel

- Customized processing methods for each steel type

Challenges in steel milling and how we solve them

Hardness and wear resistanceSteel can be challenging to machine due to its high hardness. We use advanced cutting tools and custom cutting parameters to optimize tool life and surface finish.

Chip removal and cooling: Effective cooling is essential when milling steel to prevent premature tool wear. We use high-pressure cooling and optimized cutting angles to ensure stable production.

Precision and tolerances: In CNC milling, we work with tight tolerances and advanced measurement technology to ensure high repeatability and quality.

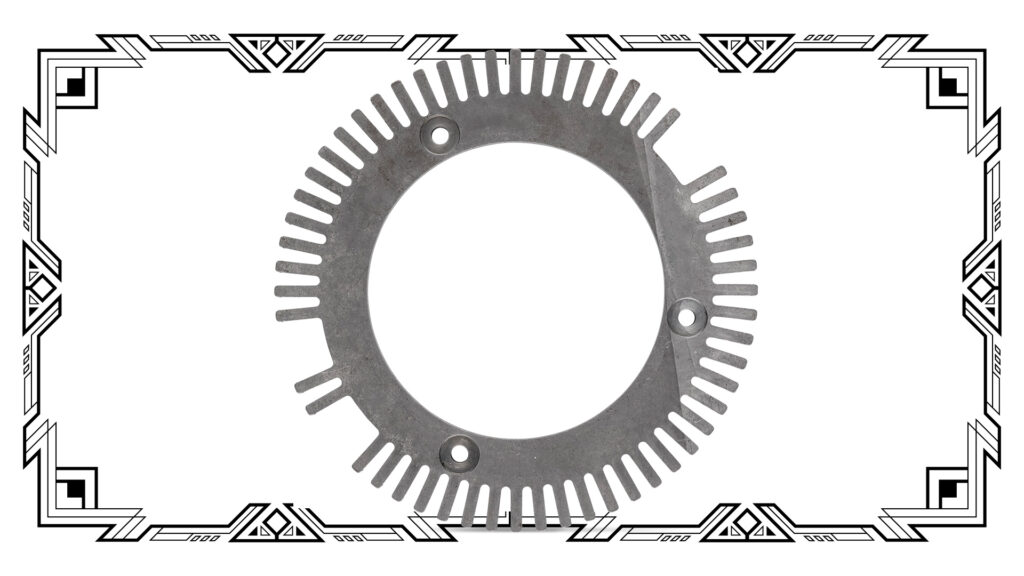

Useful tips for machinists when milling steel

To achieve the best possible results when milling steel, it is important to use the right technique and tooling strategy. Here are some concrete tips:

- Choose the right cutting data: When milling high-strength steel, the cutting speed should be between 80-120 m/min, while stainless steel usually requires 50-90 m/min depending on the alloy.

- Customize the feed: For roughing, the feed can be set to 0.1-0.3 mm/tooth, while finishing often requires 0.05-0.1 mm/tooth for the best surface finish.

- Use tools with a coating: PVD coated cutting tools are ideal for wear-resistant steels and significantly improve tool life. For stainless steel, TiAlN coatings can provide better heat resistance.

- Optimize the cutting depth: For maximum efficiency in roughing, the depth of cut should be 2-5 mm, while finishing is often between 0.2-1 mm.

- Stable clamping: Ensure that the workpiece is properly clamped with as short a projection as possible to minimize vibration and improve accuracy.

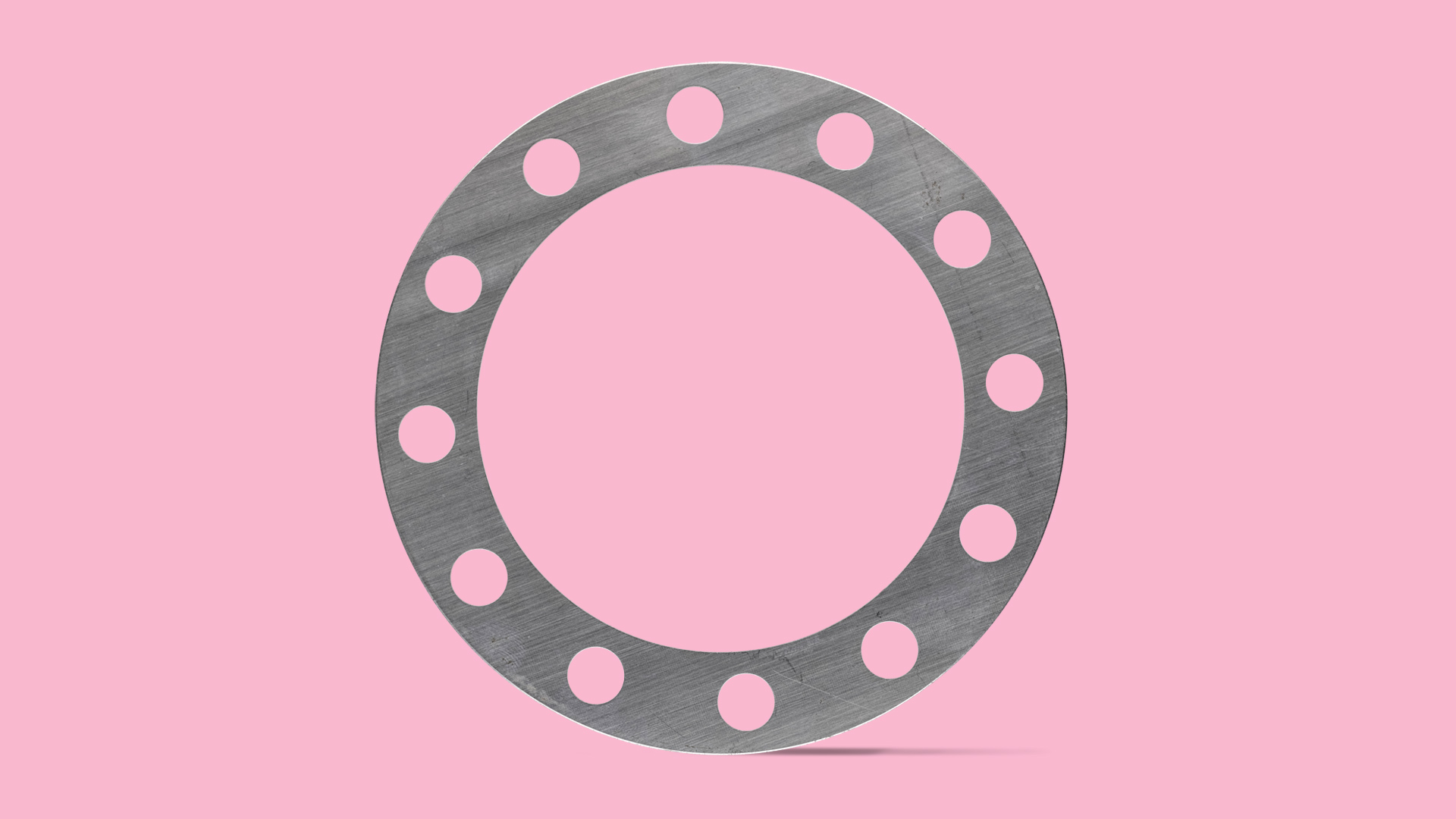

CNC milling at Thor Ahlgren

We offer advanced CNC milling with machining size up to X=1016 mm, Y=508 mm and Z=635 mm. Our production capacity covers everything from prototyping to mass productionmaking us a flexible and reliable partner for industrial milling needs.

Why choose us?

- Over 100 years of experience in metalworking

- High precision and advanced CNC technology

- Sustainability in focus - we measure our carbon footprint at item level

- Customized solutions for different steel types and complex components

Contact us for more information

Do you need a reliable partner for milling of steel? We help you find the best solution for your project.

Contact us and we will help you