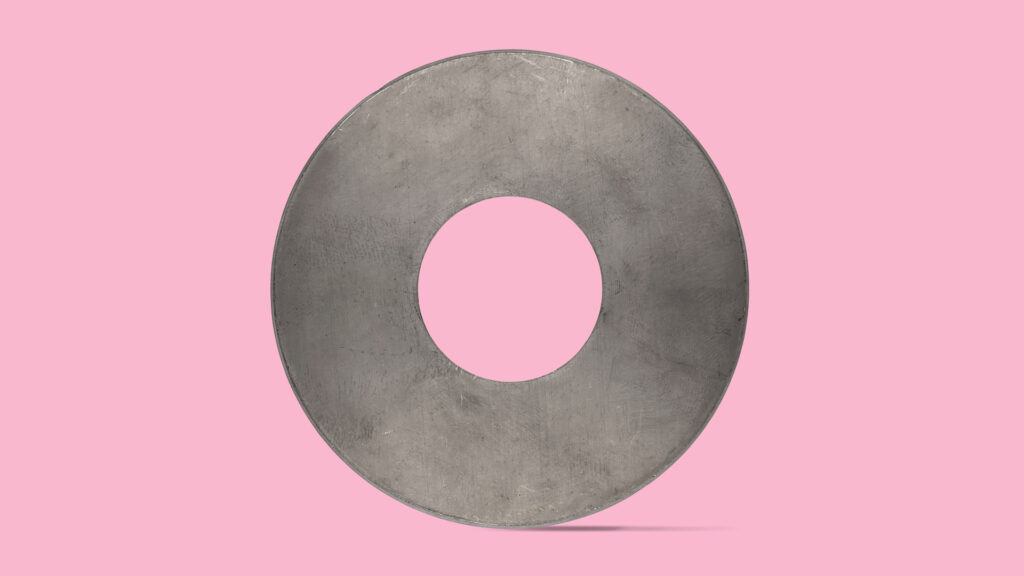

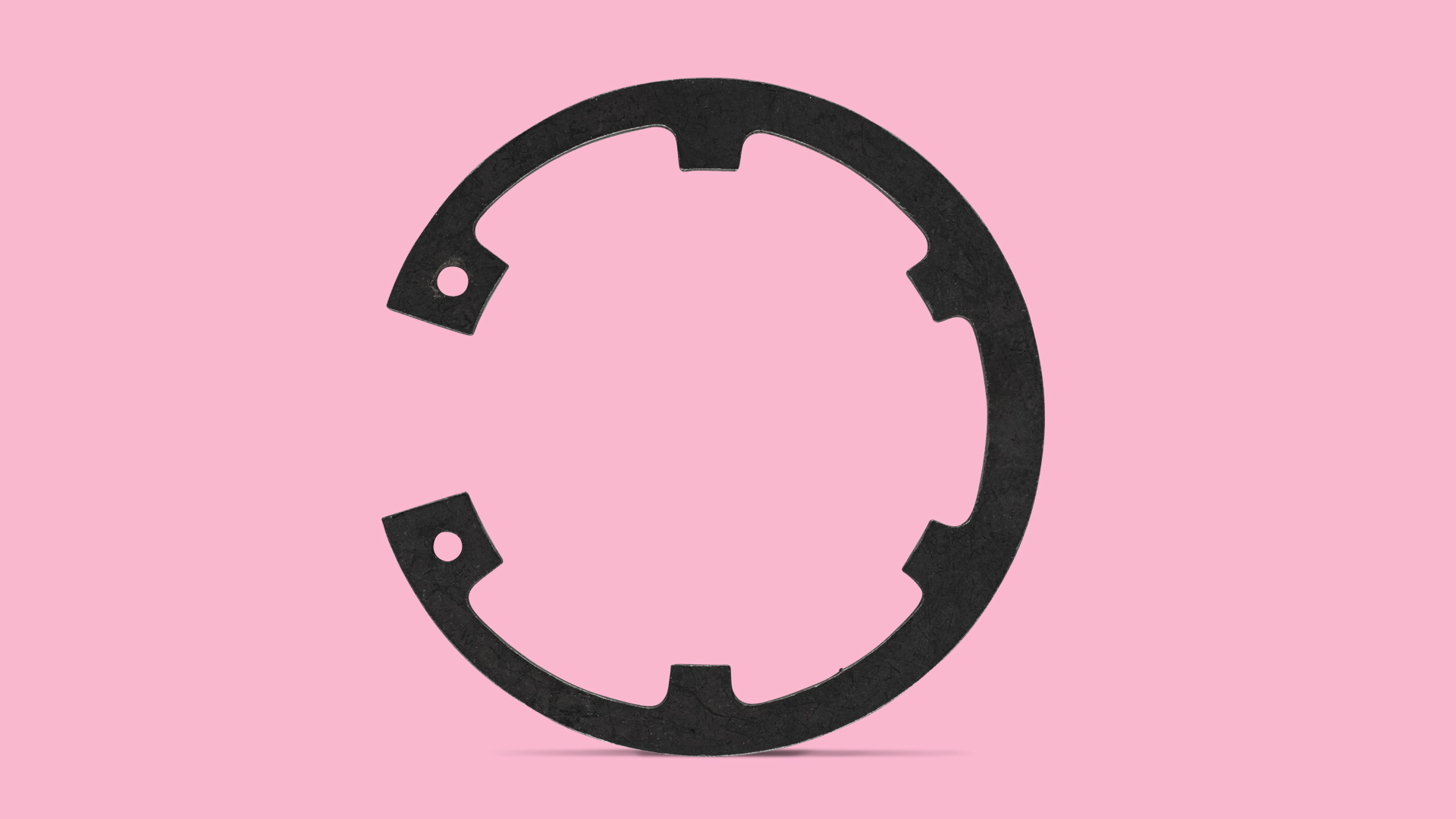

Punching aluminum

Complex or simple, you decide...

Stamping is one of the most cost-effective and precise methods for processing aluminum in large volumes. With modern technology and carefully optimized processes, we can Thor Ahlgren offer an efficient production solution for both simple and complex parts. But what factors influence the outcome of aluminum stamping, and how to ensure the best possible quality?

What we can punch

Made of steel, hardenable steel, stainless steel, high strength steel, copper, brass, aluminum

Thicknesses down to 0.10 mm

Up to 1 500 MPa ultimate tensile strength without subsequent hardening

High demands on flatness and tolerance

Contact us

Contact us and we will help you

Which aluminum alloy is best for stamping?

Aluminum is a lightweight and versatile material, but the choice of alloy has a big impact on its suitability for stamping. Hard alloys like 6000 series (e.g. EN AW-6082) may require higher pressing force but provide a durable product, while softer alloys such as 1000 and 3000 series are often more malleable and easier to work with.

Key properties of aluminum for stamping:

- Moldability - Affects how easily the material can be shaped without cracking.

- Crime limit - A higher crime threshold requires more pressure.

- Hardness and surface finish - Affects tool life and final product quality.

A common objection is that stamping does not work for all aluminum alloysbut with the right choice of alloy and process, even difficult-to-machine aluminum grades can be punched efficiently.

How we punch aluminum efficiently?

To ensure precision and production speed, we use automatic presses with precise punching tools. But which parameters are crucial?

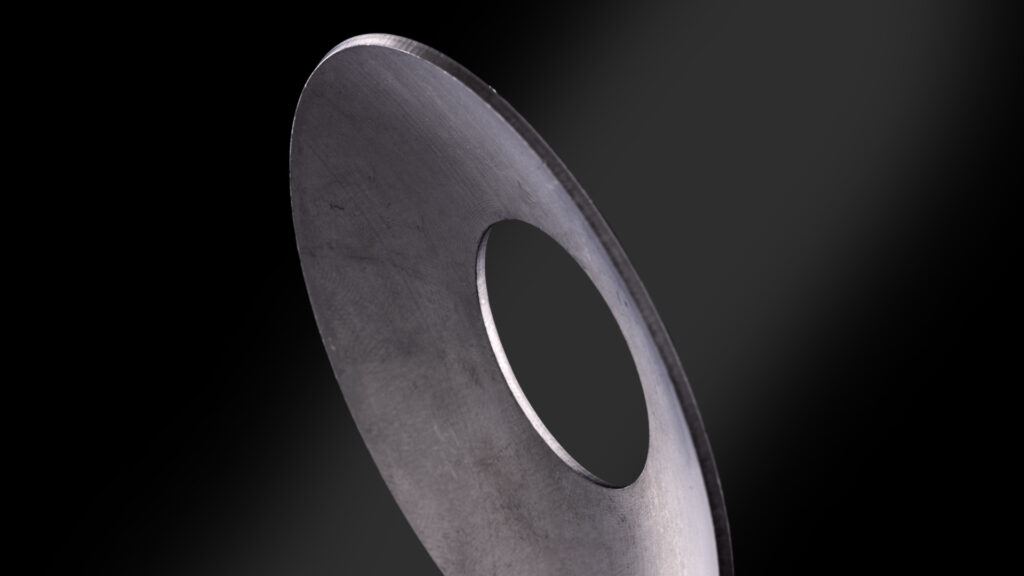

What pressing force is required to punch aluminum?

The pressing force depends on the sheet thickness, hole size and the material's tensile strength. Generally speaking:

- Thinner aluminum (<1 mm) requires less pressing force and causes minimal wear on tools.

- Thicker aluminum (>3 mm) requires higher pressing force and more careful tool selection to avoid deformation.

How to reduce deformation during punching?

Aluminium has a tendency to deform during stamping if the process parameters are not optimized. To minimize this, we use:

- The right punching tool - Precise tolerances and sharp cutting edges reduce the risk of deformation.

- Optimized pressing force - Neither too high nor too low power for best results.

- Support devices - Prevents thin sheets from bending during punching.

Some people believe that hydraulic punching machines are too slowHowever, these machines offer higher precision and less tool wear, which can save costs in the long run.

Punching vs. laser cutting

When choosing a method to process aluminum, many companies face the question of punching or laser cutting is the best option. Both methods have their advantages, but for large batches and high production rates, die-cutting is usually the most economical choice.

Advantages of punching compared to laser cutting:

- Higher production speed - Punching can process multiple parts per stroke, while laser cutting must cut each contour individually.

- Lower production costs for large series - Lower energy consumption and material waste make die-cutting more cost-effective in volume production.

- Reduced heat impact - Laser cutting can cause heat build-up in the material, which can affect precision and surface quality.

- Possibility of forming and threading - With the right tools, punching can create details with embossed shapes, which is difficult to achieve with laser cutting.

Laser cutting can be an excellent option for complex and low-volume productions where flexibility is crucial. But when it comes to cost-effective mass production of aluminum parts punching is usually the best solution.

How to achieve the best hole tolerance?

To ensure accurate holes and minimal rework is required:

- The right tooling materials - High performance steel (HSS) or carbide for longer life.

- Low clear dimensions - Correctly set tolerances to reduce the risk of incorrect dimensions.

- The right plate thickness - The ratio of hole size to sheet thickness affects the result. Rule of thumb: the hole diameter should be at least as large as the sheet thickness.

Which machines are best for punching aluminum?

On Thor Ahlgren we use automatic presses with the capacity to process:

- Material thicknesses from 0.10 mm and up

- High-strength alloys up to 1 500 MPa ultimate tensile strength

- Products with high flatness and tolerance requirements

Common problems in aluminum stamping - and how to solve them

High wear and tear on tools → Use wear-resistant coatings and optimize lubrication.

Material deformation → Adjust pressing force and use support tools.

Slow production time → Automate and optimize the punching process.

Difficult to achieve the right tolerances → Invest in high-quality tools and careful process control.

Uncertainty about process choice → Consult experts to choose the right method and machine.

Why you should choose Thor Ahlgren

We are more than a supplier - we are a strategic partner. With our focus on sustainability, advanced technologies and customized solutions, we ensure that your production is both efficient and profitable. Our teams of experts work closely with you to optimize material choices, tolerances and production flows.

👉 Need a reliable partner for aluminum stamping? Contact us today for a free quote and let us optimize your production!