Hardening of metals

According to your wishes...what is your need?

At Thor Ahlgren, it all starts with our heritage and tradition in metalworking. With decades of experience behind us, we combine craftsmanship with modern technology to create the highest quality products. We offer professional hardening services to ensure your components meet the highest standards in the industry - and it's not just about technology, it's about passion and precision!

Contact us

Contact us and we will help you

Our experience and expertise in curing

With over 30 years of experience in metalworking - including tumbling, vibratory tumbling, surface grinding and hardening - we have an understanding of industry requirements that goes beyond technology. We work with precision and craftsmanship at every stage. Our collaboration with leading researchers and industry specialists allows us to combine the best of traditional hardening with innovative solutions. This means you can count on quality and reliability throughout the process. Our certified equipment and processes ensure the highest standards in every project we take on.

Different methods and curing processes

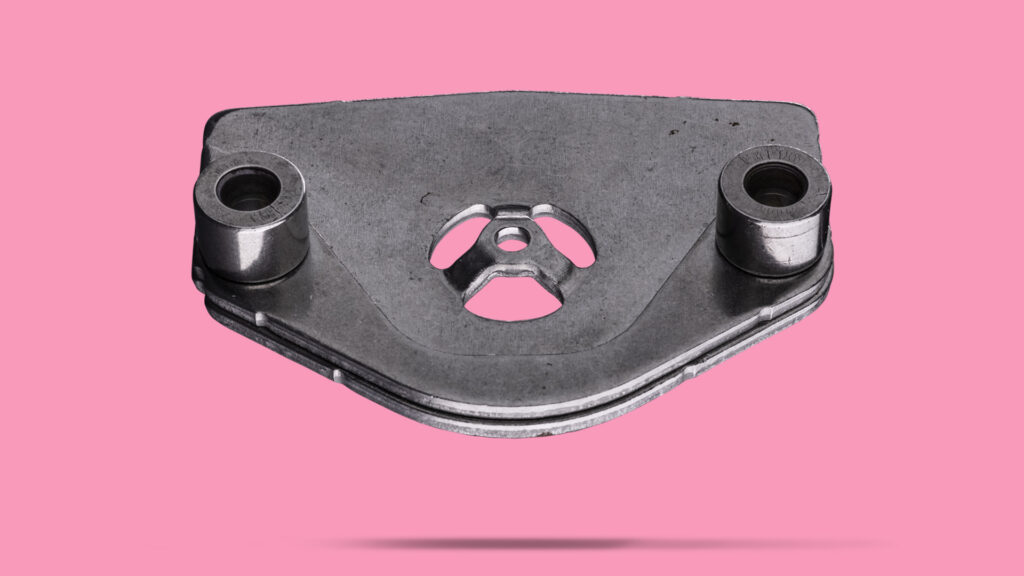

In hardening, there is no one-size-fits-all method; each material and each end product requires its own specific solution. At Thor Ahlgren, we customize each process to ensure optimal performance and longevity. Below is an overview of the most common methods and how we combine tradition and technology to create better products:

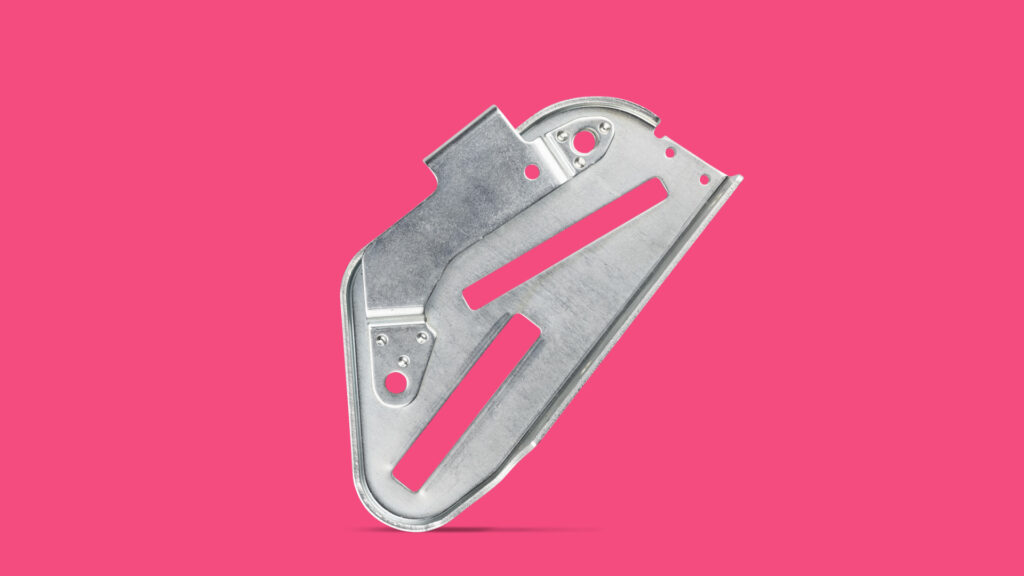

- Heat treatment: One of the most flexible and cost-effective processes to increase hardness and toughness, especially for steel. This method has its roots in traditional craftsmanship but with today's technology we can perform it with a higher accuracy.

- Protected curing: A controlled environment that minimizes oxide formation and ensures the desired properties of the material. This is a method we developed for components where surface quality is crucial.

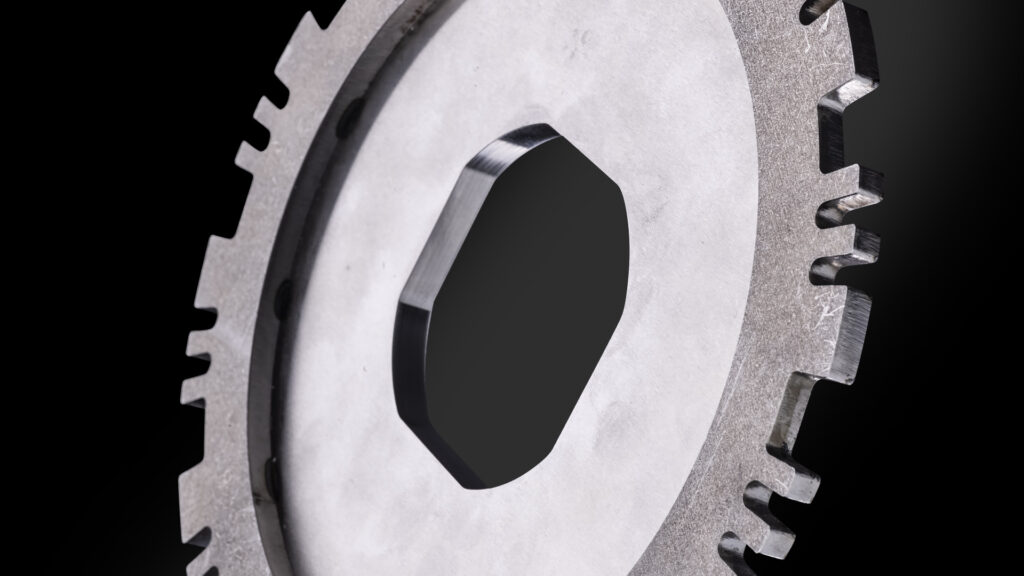

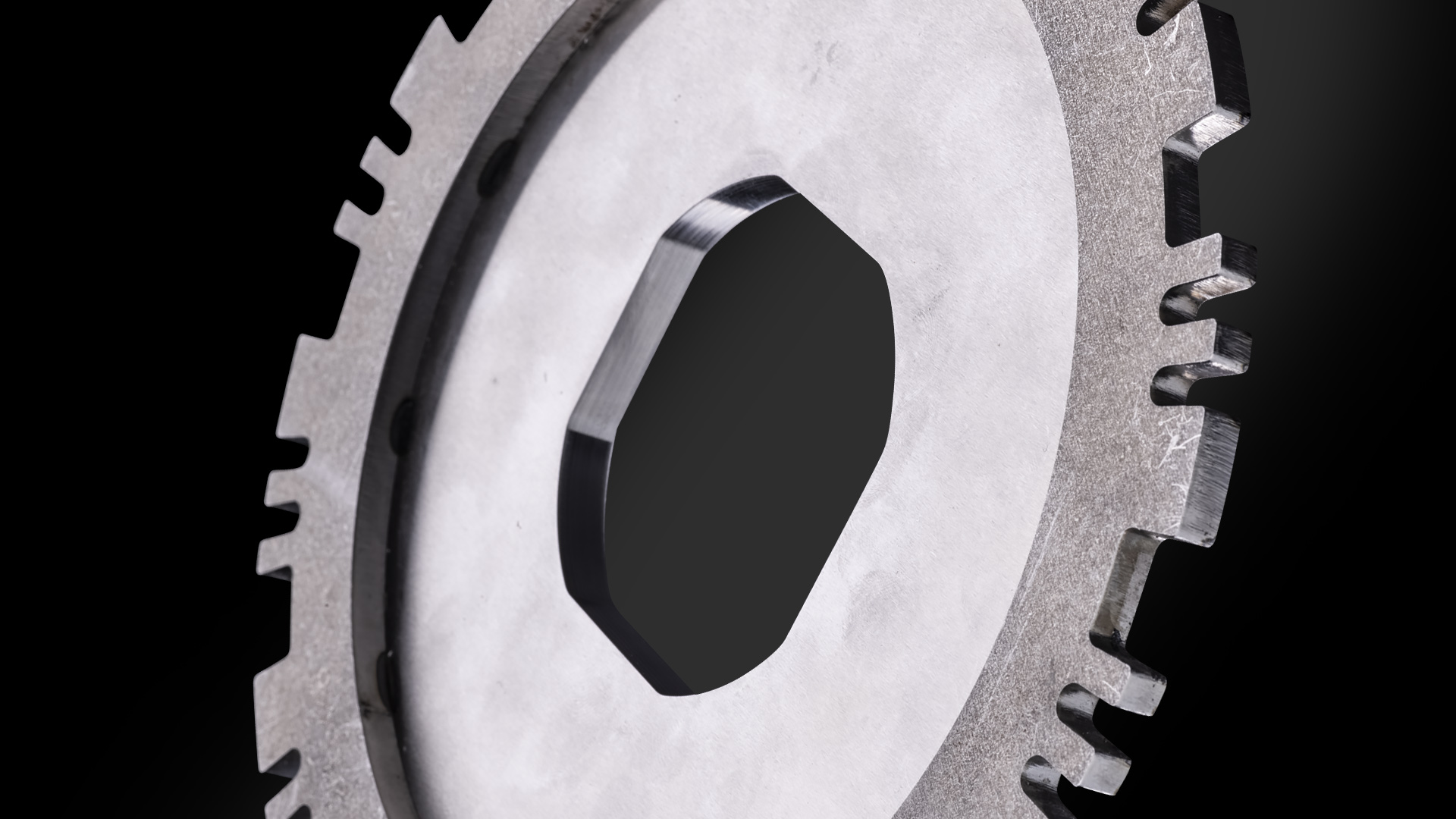

- Induction hardening: A fast and precise method for specific surfaces. It is ideal for high-precision parts such as shafts and gears - components that require maximum wear resistance. Our modern induction technology enables both speed and accuracy.

- Surface hardening: Provides a durable surface while maintaining toughness inside the material, giving a perfect balance between hardness and flexibility. We're refining this method to create products that withstand heavy wear without sacrificing mobility.

Benefits of curing

Our hardening services offer a range of key benefits that take your components to the next level:

- Increased strength and longevity: Hardening makes your components more resistant to wear and tear. The result? Fewer replacements and less wear - which both reduces costs and increases efficiency.

- Cost-effectiveness: By increasing the lifetime of your components, we reduce your maintenance costs and maximize the value of your investment.

- Versatile use: From automotive to construction and medical equipment, hardening is a crucial part of creating products that meet high standards. Our solutions are always customized to your specific requirements and industry needs.

Why choose Thor Ahlgren for curing?

At Thor Ahlgren, we are all about combining tradition and modern innovation. We work with materials in a way that honors our heritage in craftsmanship, while integrating the latest technology to give our customers the best possible solution. With our long experience, certifications and customer-focused approach, we always guarantee the highest quality and reliability.

Contact us

Do you want to maximize the potential of your materials and create sustainable, high-performance solutions? Contact us at Thor Ahlgren for a free consultation and material analysis! We look forward to being your partner for metal processing and quality-enhancing finishing.