Laser cutting in Småland

From prototype to mass production, which do you prefer?

Are you looking for a reliable partner for laser cutting in Småland that offers high precision and the possibility of post-processing? Thor Ahlgren combines modern technology with a dedicated team with extensive experience in sheet metal processing. We deliver complete solutions - from prototype to series production - with quality and accuracy at every stage.

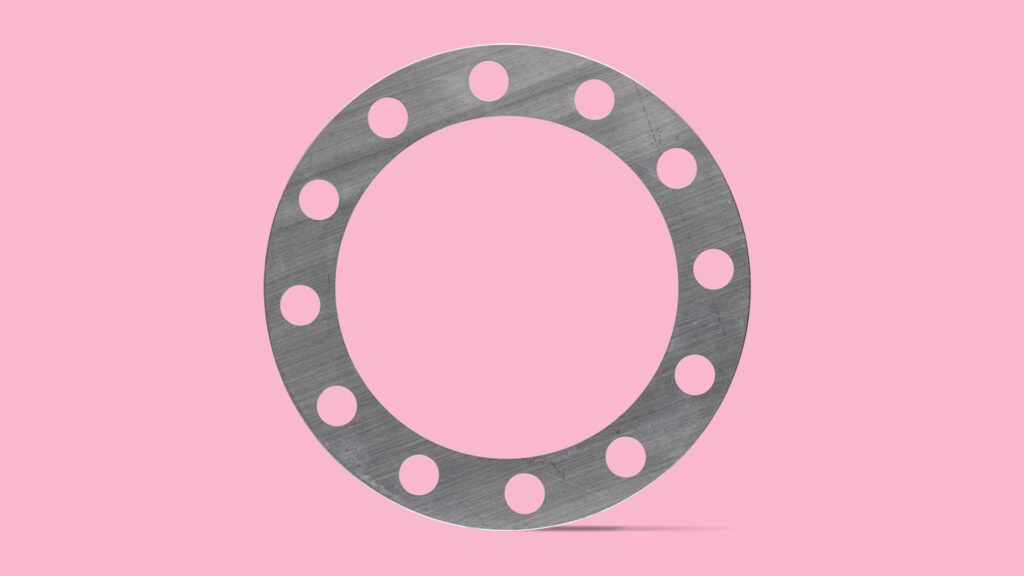

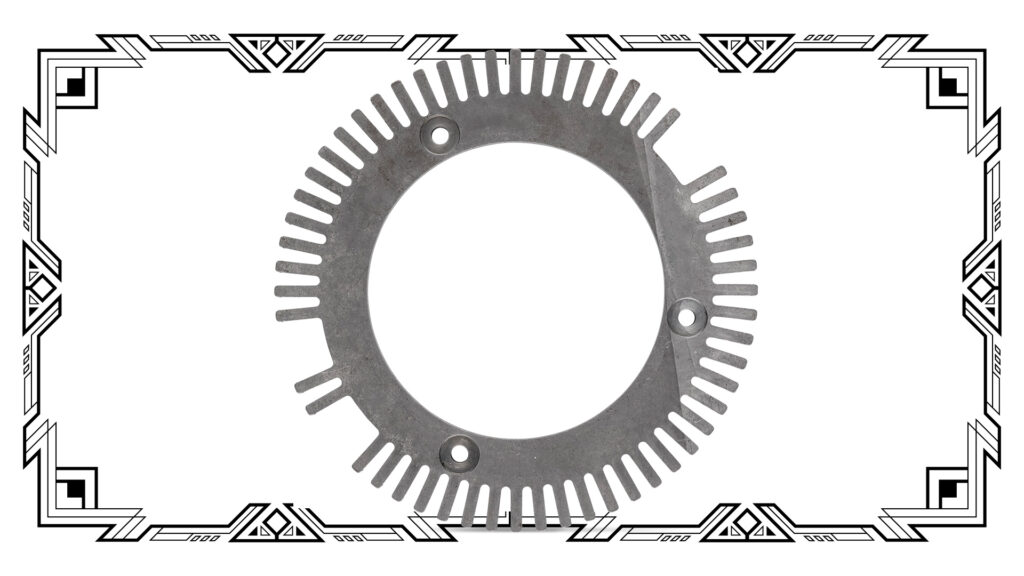

Product features laser cutting

Material, sheet metal, black plate, extra high strength steel, wear plate, heavy plate, blanks, stainless and aluminum

Sheet thickness up to 25 mm black sheet

Max sheet size 3000*1500mm

Contact us

Contact us and we will help you

What is laser cutting and why choose it?

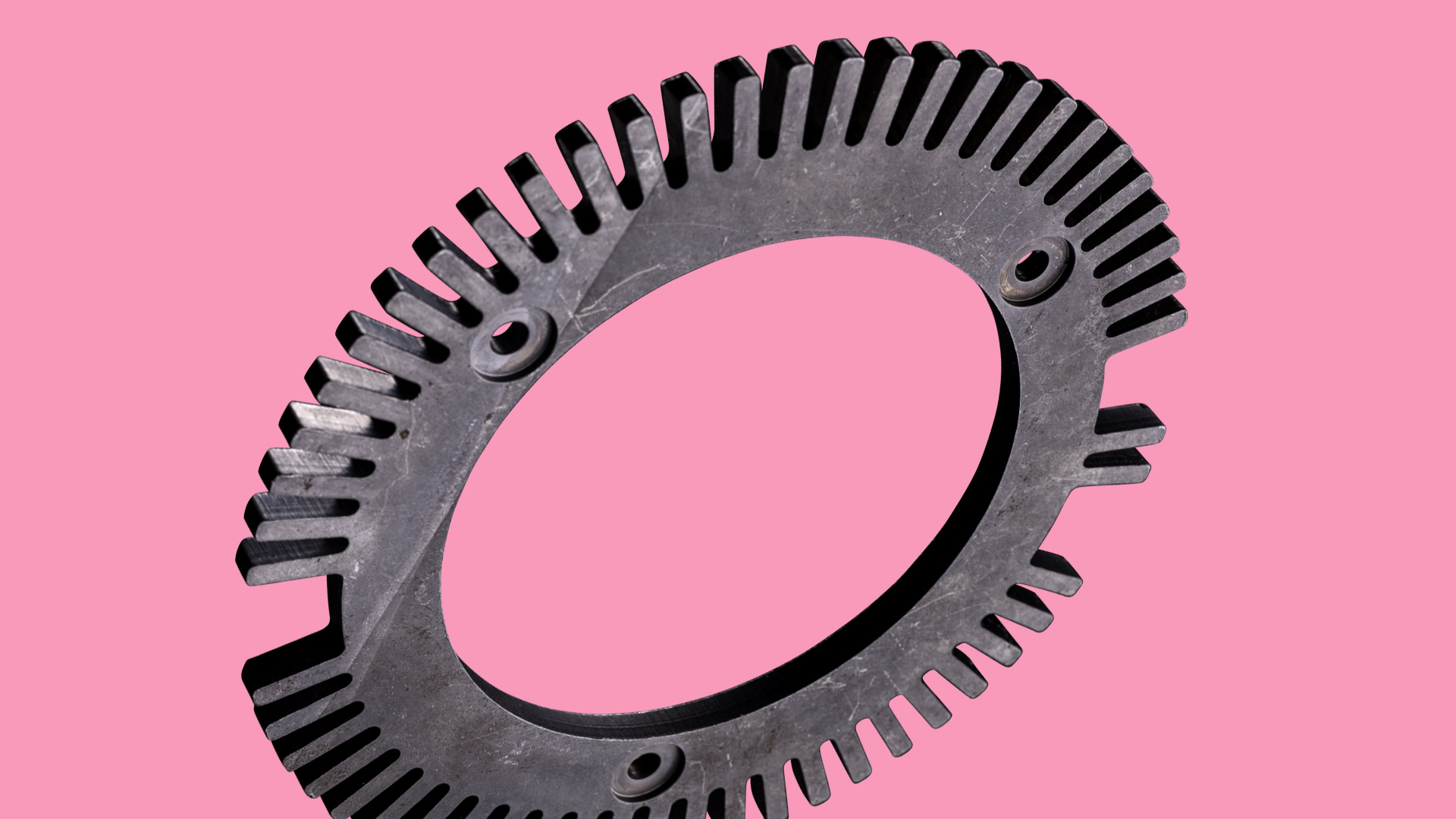

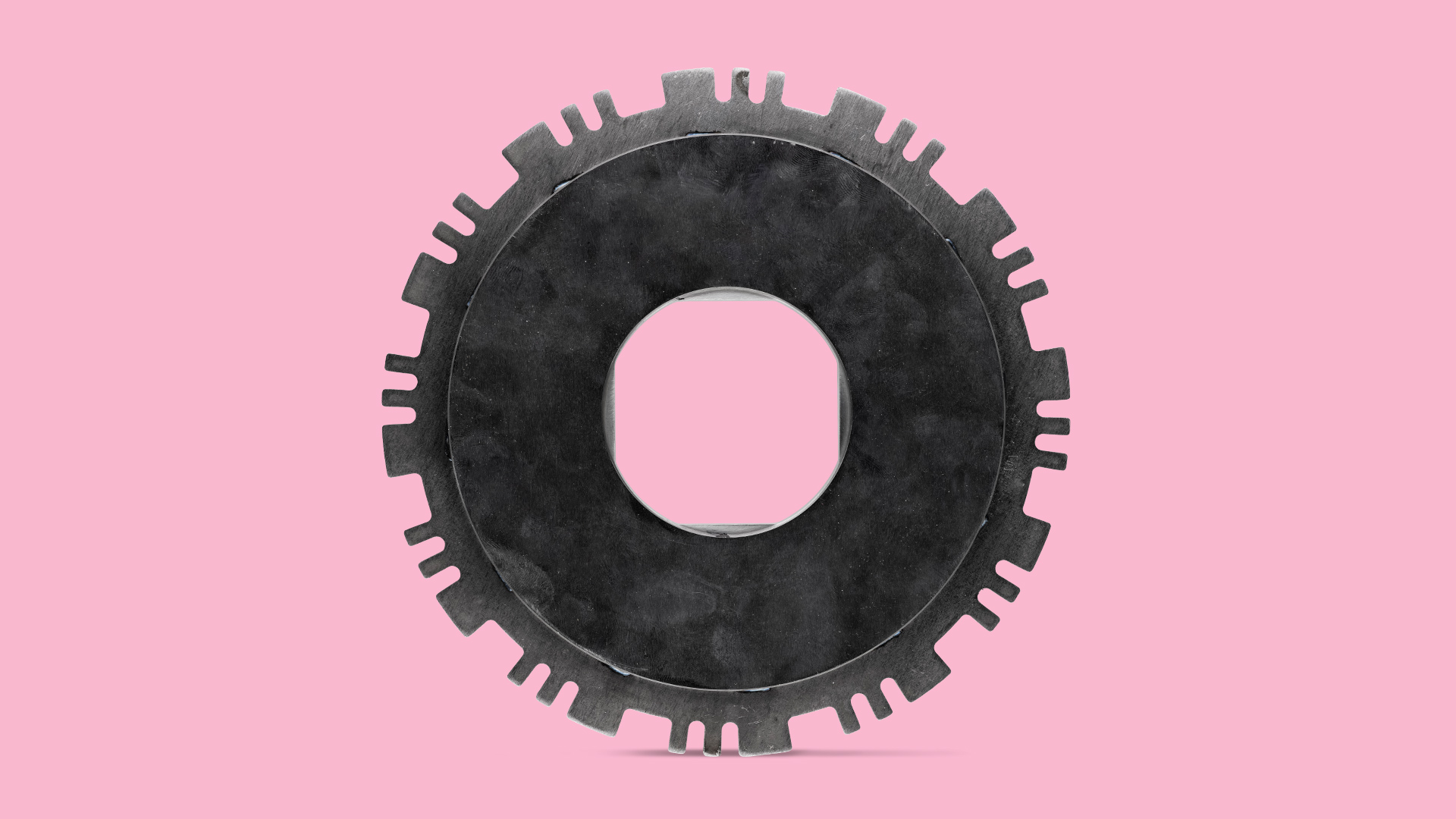

Laser cutting is a precision method where a laser beam cuts through materials such as sheet metal, aluminum and stainless steel to create complex shapes with precise cuts. Compared to traditional machining methods, laser cutting produces thin cuts with minimal impact on material properties, which is ideal for products where precise tolerances and clean edges are crucial.

With our modern laser equipment, we can process sheet thicknesses up to 25 mm for black plate and other materials. Our machines can handle sheet sizes up to 3000×1500 mm, enabling both large and small projects with the same precision and care.

Complete solutions in sheet metal processing

Thor Ahlgren is more than just laser cutting. We offer complete solutions in sheet metal processing, which means that we handle everything from cutting and milling to post-processing. The combination of figure cutting and finishing in our milling machines makes us a flexible partner that can deliver finished components ready for assembly.

Advantages of laser cutting

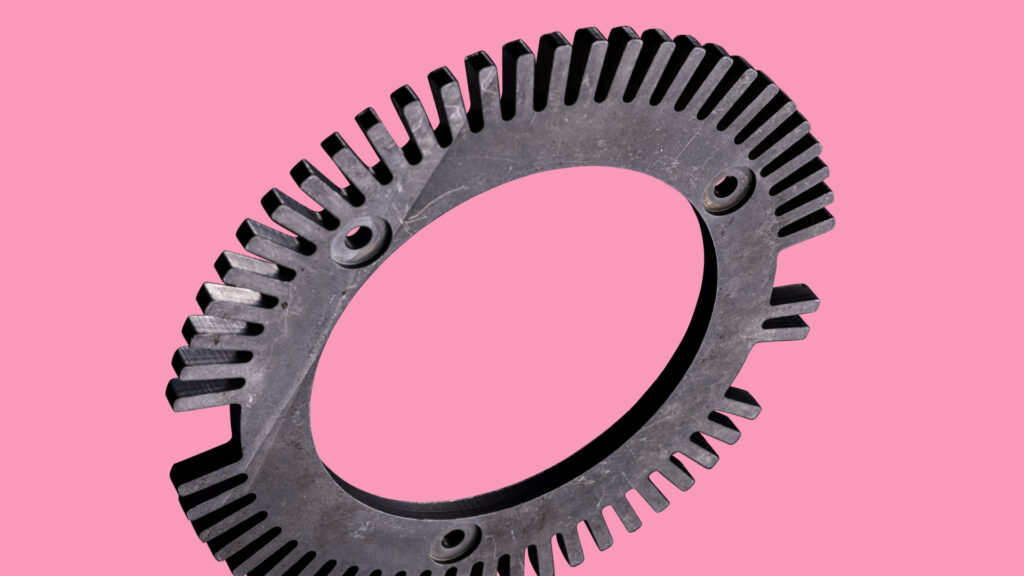

- High precision and complexityLaser cutting provides precise and complex cuts, making it ideal for automotive parts, building components and customized metal products.

- Flexibility in material choice: We handle a wide range of metals, from black plate to stainless steel and aluminum, which allows us to adapt production to your specific needs.

- Efficient post-processing: After laser cutting, we offer milling, which provides a smooth and finished surface ready for further use.

Fine blanking and pressing

In addition to laser cutting, Thor Ahlgren also offers punching, pressing and fine blanking. These methods are optimal for products that require high precision in shape, depth and surface. Fine blanking is particularly beneficial when high quality functional surfaces and tight tolerances are required. This allows us to offer complete solutions for sheet metal processing.

Why choose Thor Ahlgren?

Thor Ahlgren is more than a supplier - we are a partner who understands the importance of precision and quality at every stage. Our modern machinery and expertise in laser cutting, punching and milling allow us to offer competitive prices without compromising on quality. We handle everything from small series to volume production and deliver complete solutions with ready-to-use parts.

Contact us for more information

Do you need high-precision laser cutting in Småland? Contact Thor Ahlgren today for a free consultation and see how we can help you from prototype to series production. We are here to answer your questions and find the best solution for your project.