Laser cutting

From prototype to mass production, which do you prefer?

Figure cutting in sheet metal with the possibility of post-processing in a milling machine.

Product features laser cutting

Material, sheet metal, black plate, extra high strength steel, wear plate, heavy plate, blanks, stainless and aluminum

Sheet thickness up to 25 mm black sheet

Max sheet size 3000*1500mm

Contact us

Contact us and we will help you

Laser cutting of steel

At Thor Ahlgren, we see steel as a malleable material, like the old masters in the early days of industry. We have embraced the legacy of the early industrial years and combined it with modern technology. At the same time, we have preserved the spirit of hard work and craftsmanship that characterized those times. Through our laser process, we produce parts that meet customer requirements - from simple to complex geometries

Why choose Thor Ahlgren?

- Innovation and precision: From prototype to mass production.

- Material diversity: Steel, high-strength steel, stainless steel, copper, brass or aluminum - we handle it all.

- Environmental considerations: Our sustainability strategy is integrated into every step of production. We measure our CO2 footprint and strive for sustainable business and a pleasant working environment.

Our services in laser cutting

Do you have an article that needs laser cut in Småland? We specialize in production customization to ensure that production is as efficient as possible and according to your specifications. With our machines, we laser cut parts with precision in shape and surface. In case of high tolerance requirements, we can further process the cut blank in our CNC machines. Whether it is a small or large series, we always deliver with the agreed precision.

What is laser cutting

Laser cutting is a versatile technique used to cut various materials, mainly metals. The technique uses a concentrated laser beam to melt, vaporize or burn away the material. It results in high-precision cuts. The method is particularly useful for complex shapes and detailed patterns that are difficult to achieve with traditional mechanical cutting tools.

Tradition and heritage

Thor Ahlgren AB has a long history of metalworking. We build on decades of experience and tradition, making us a reliable partner for our customers. Our wealth of knowledge in metalworking has been passed down through generations, ensuring the highest quality in every project.

How laser cutting works

Laser cutting involves the use of a high-energy laser beam, often generated by carbon dioxide (CO2), fiber or ytterbium. The beam is focused through lenses or mirrors to obtain a small spot of high energy density. This energy-dense beam is directed at

workpiece, where it quickly heats and melts the material. By moving the jet along a predetermined path, complex shapes can be cut with great precision.

How we laser cut different materials

Sheet metal / black plate (mild structural steel)

- Cutting gas and pressureO₂ 1-4 bar (reactive).

Thickness: up to ≈ 25 mm with 6-10 kW fiber laser.

Key tips:

Put the focus in the middle of the plate.

Trim the gas pressure for minimal slagging.

Kerf offset ≈ 0.10 mm; oxide skin is ground off before welding/painting.

Extra high strength steel (AHSS > 600 MPa)

- Cutting gas and pressureN₂ 15-22 bar (inert).

- Thickness: up to ≈ 10 mm with 10 kW (require more kW for thicker).

- Key tips:

Reduce the feed rate ≈ 20 % compared to mild steel.

Keep piercing time ≤ 0.2 s for small HAZ.

Oxide-free, hard edge without soft zone.

Wear plate (Hardox/Strenx 400-600 HBW)

- Cutting gas and pressure: N₂ > 18 bar; dry compressed air < 6 mm.

- Thickness: up to ≈ 15 mm with 10 kW.

- Key tips:

Avoid O₂ (risk of overheating/annealing).

Short focus length & small nozzle gives narrow HAZ → hardness is preserved.

Heavy plate (> 20 mm)

- Cutting gas and pressureO₂ 3-6 bar (fiber or CO₂ laser).

- Thickness: up to ≈ 40 mm with ≥ 15 kW + beam-shaping.

- Key tips:

Use burst piercing and oscillation to prevent overburning.

Cutting speed 0.5-1.0 m/min at 25 mm.

Plasma or gas cutting may be more economical for extremely coarse materials.

Stainless steel (AISI 304/316)

- Cutting gas and pressure: N₂ 12-20 bar (purity ≥ 99.995 %).

- Thickness: up to ≈ 30 mm with 15 kW.

- Key tips:

Blank, passive edge without post-processing.

For < 4 mm, filtered compressed air can lower the cost (darker cut).

Focus -0.5 mm below the surface, kerf offset 0.10-0.18 mm.

Material variety and environmental considerations

We work with a variety of materials such as steel, stainless steel and aluminum. Our commitment to sustainability is reflected in our efforts to minimize waste. We cut sheet metal thicknesses from 0.35 up to 20 mm. We measure our CO2 footprint and strive for healthy business and a pleasant working environment.

Applications of laser cutting

Laser cutting is used in many industries, including automotive, aerospace, electronics, and medical. It is ideal for manufacturing components that require high precision and quality, such as automotive parts, medical implants and electronic circuit boards.

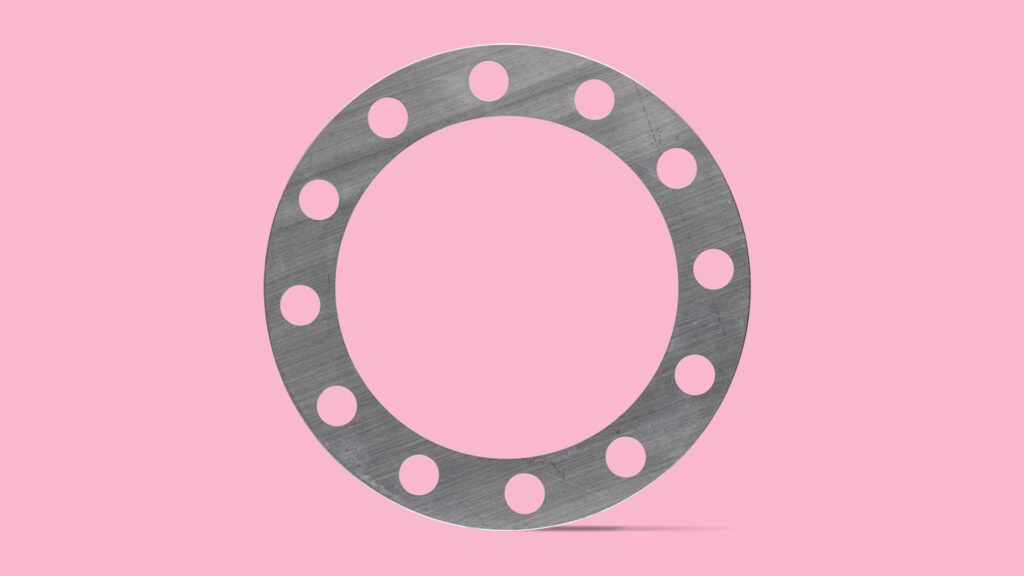

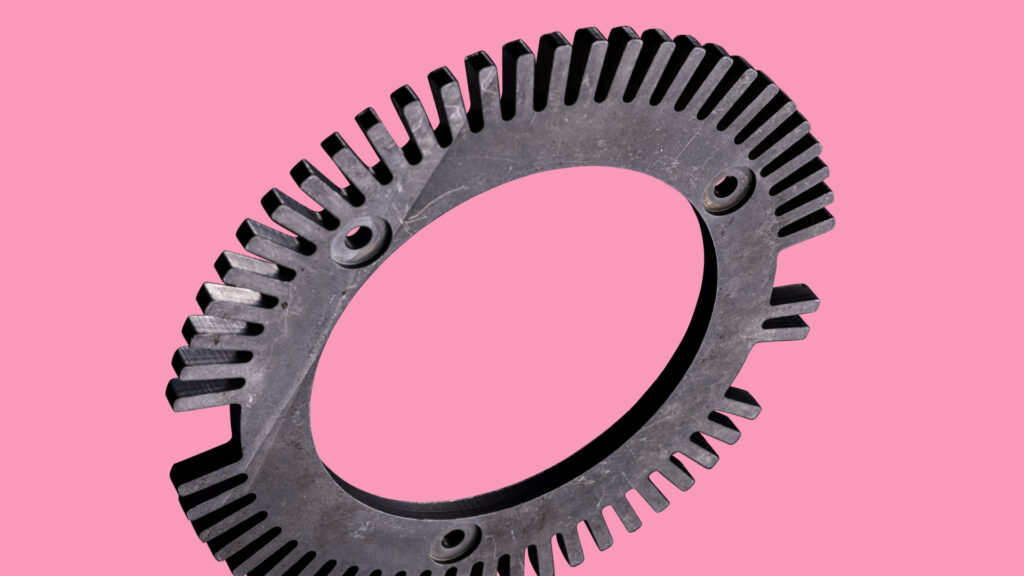

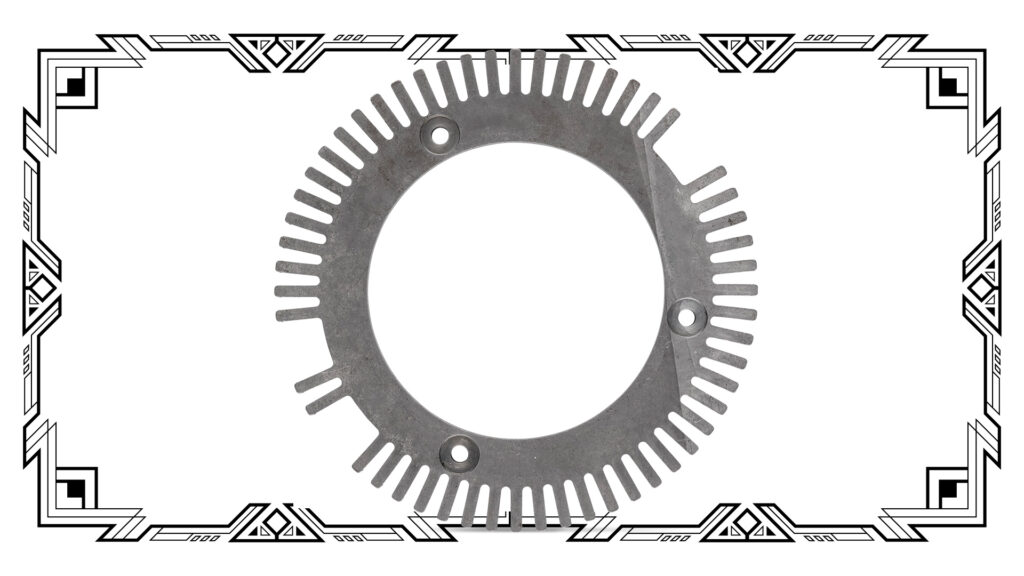

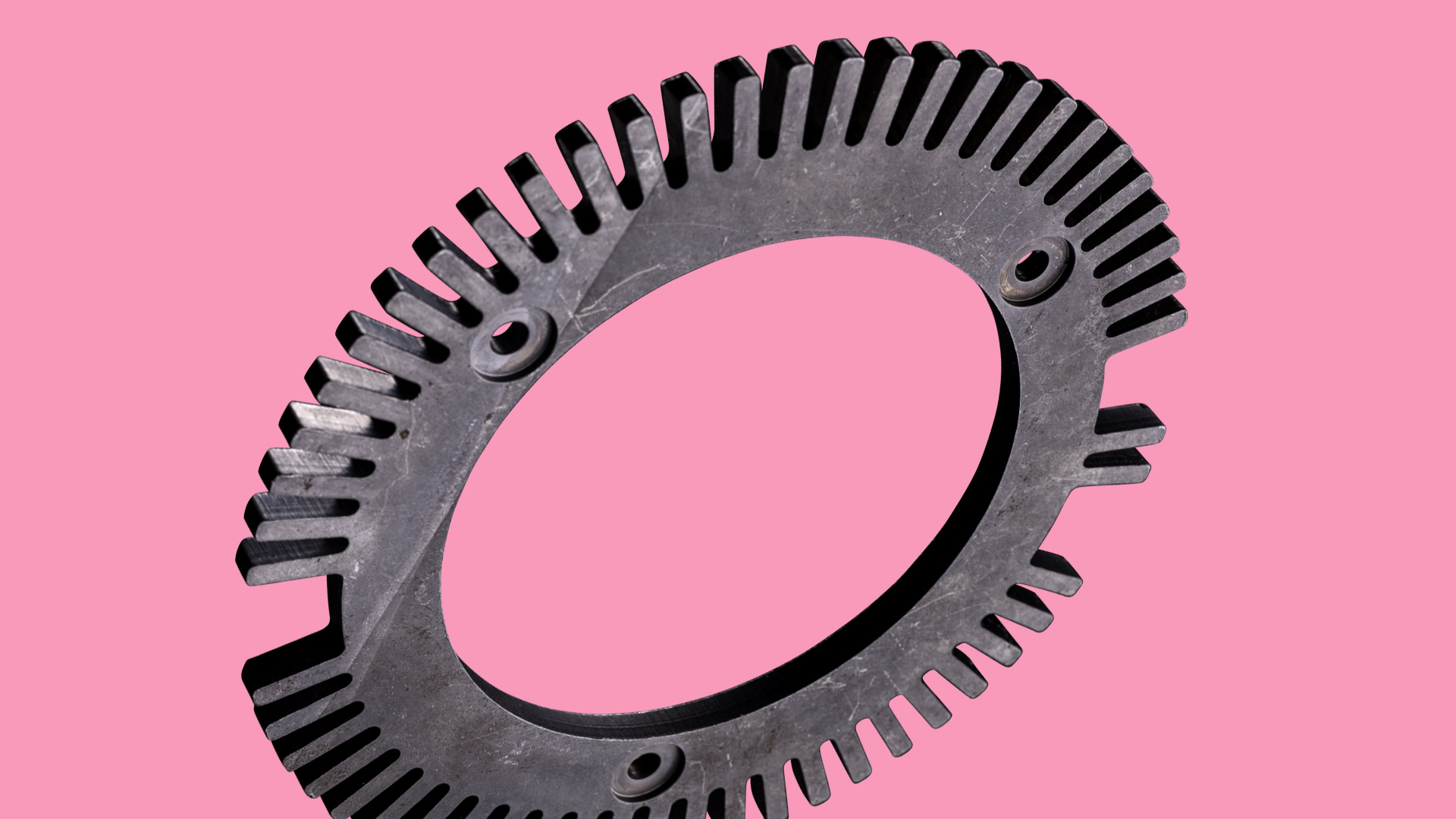

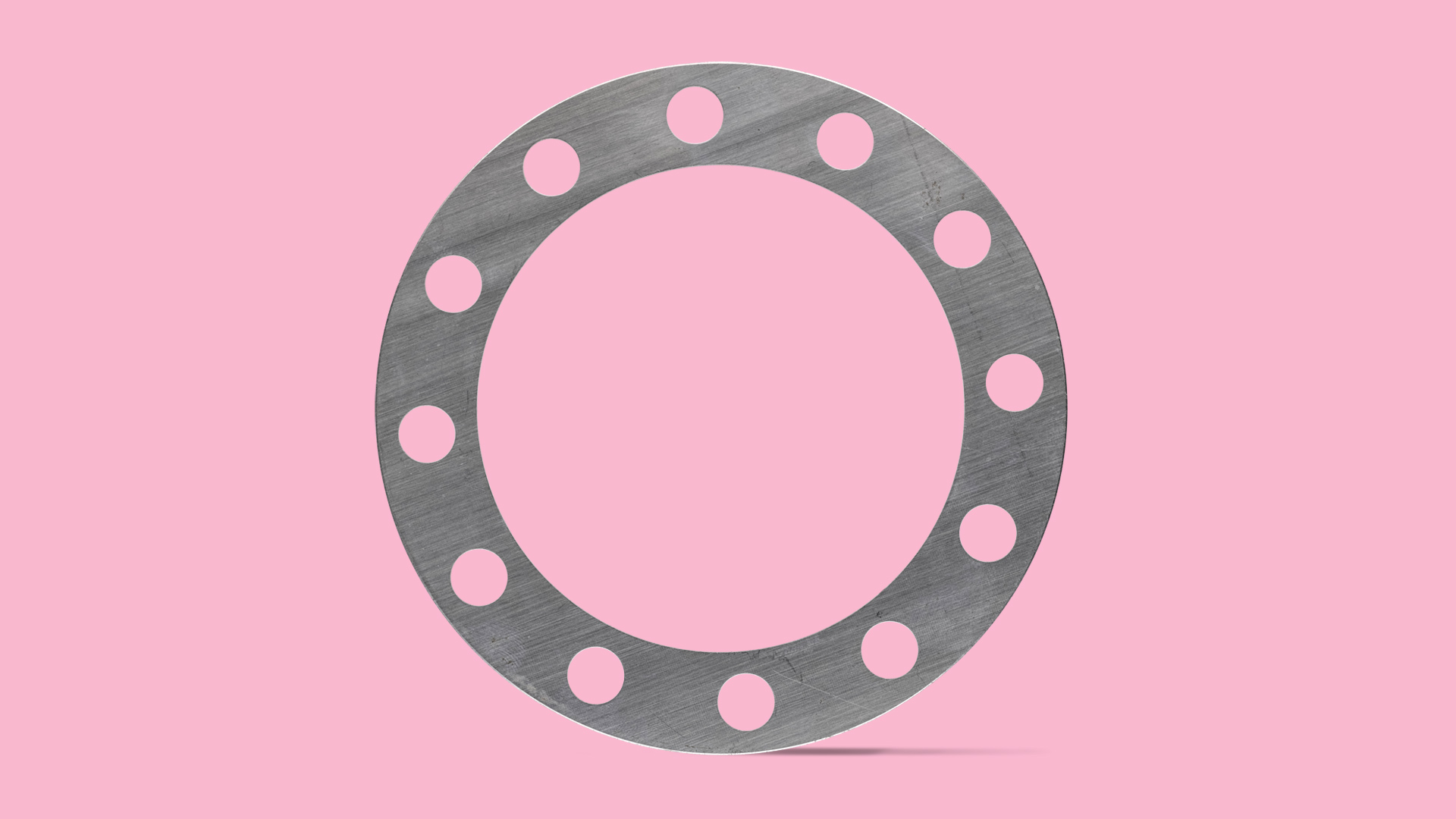

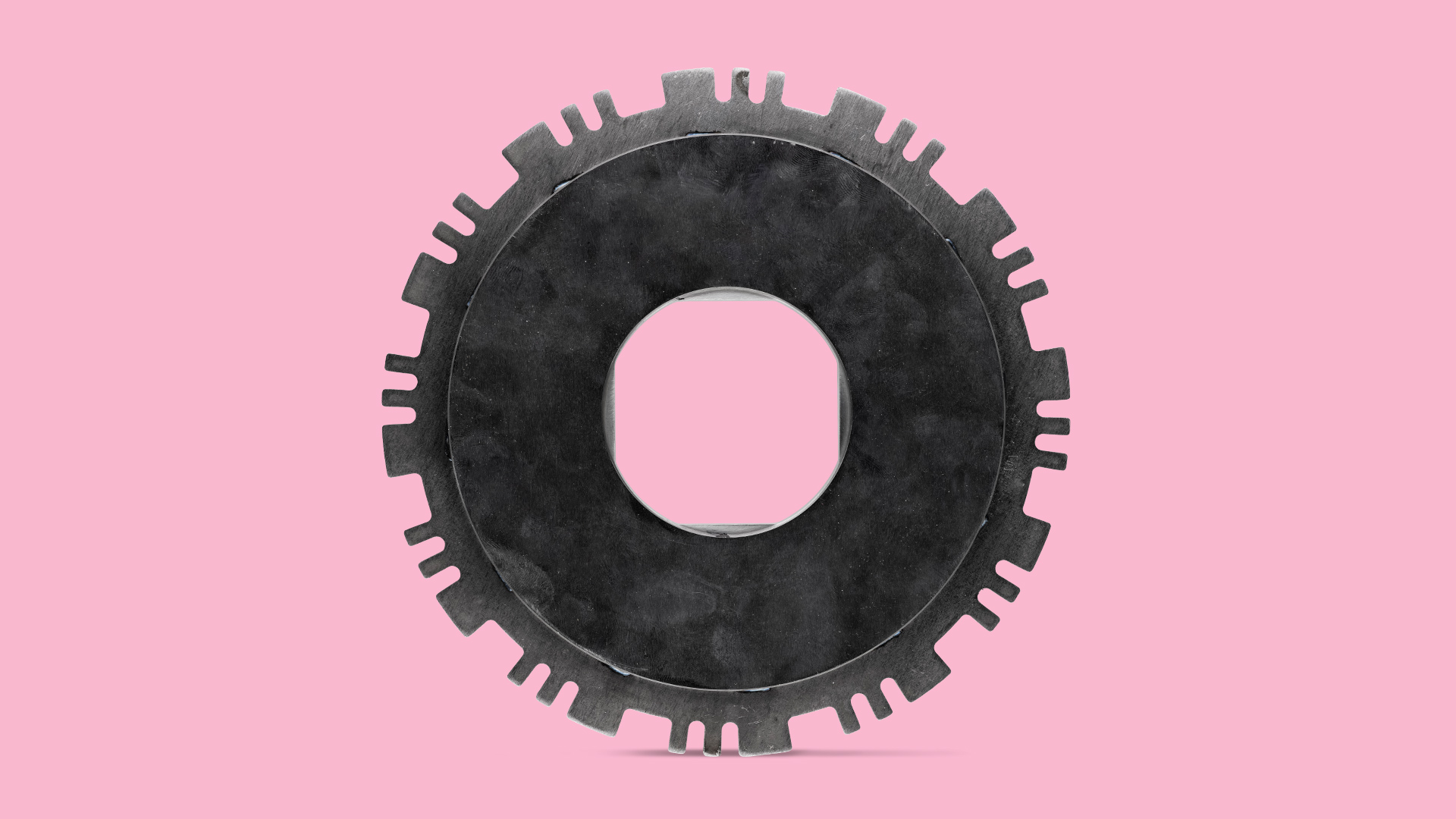

Shims and pulse wheels in laser-cut sheet metal

We often manufacture shims and pulse wheels using laser cutting, especially in thinner sheet metal where high dimensional accuracy is required. Laser cutting enables the production of parts with tight tolerances and good repeatability. If necessary, the process is complemented by CNC machining to achieve the right fit or surface finish.

Contact us for more information

If you are interested in learning more about our laser cutting services or would like to discuss how we can help your business, contact us today. We look forward to working with you to fulfill your needs for high-quality cutting solutions.