Laser cutting in stainless steel

Since 1918, Thor Ahlgren has been a trusted partner in metalworking. Our heritage is based on craftsmanship, tradition and a constant quest to be at the forefront of modern technology. Today, we are proud to offer advanced laser cutting in stainless steel, a method that combines precision and efficiency to deliver top-class results. Read on to discover how we can help you achieve your project goals.

Contact us

Contact us and we will help you

Why choose laser cutting in stainless steel?

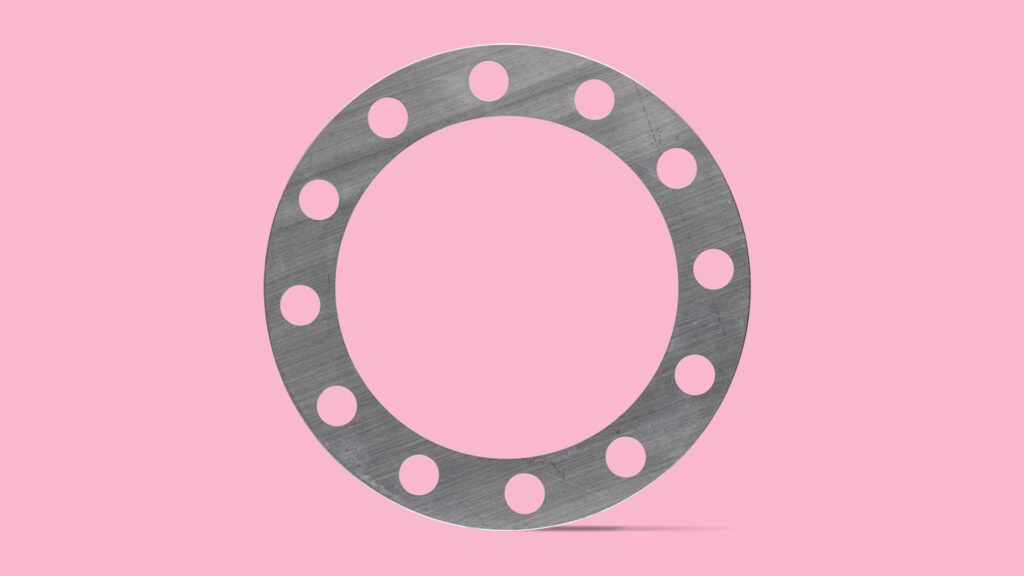

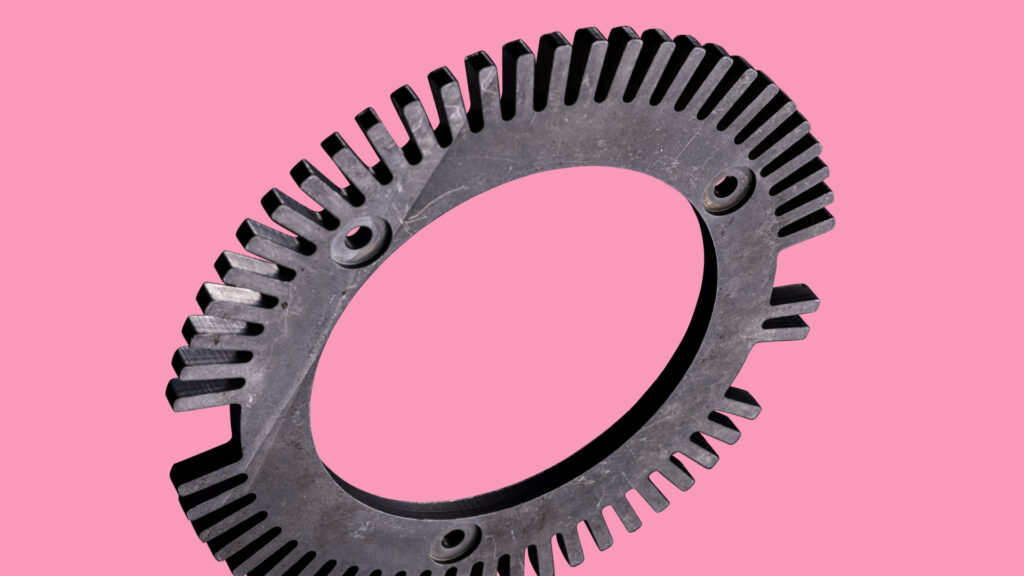

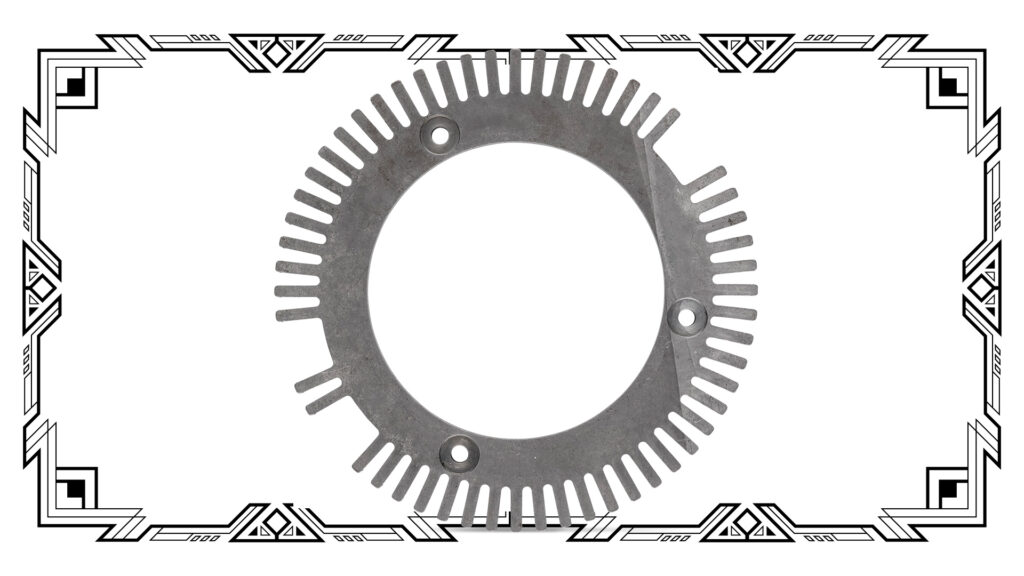

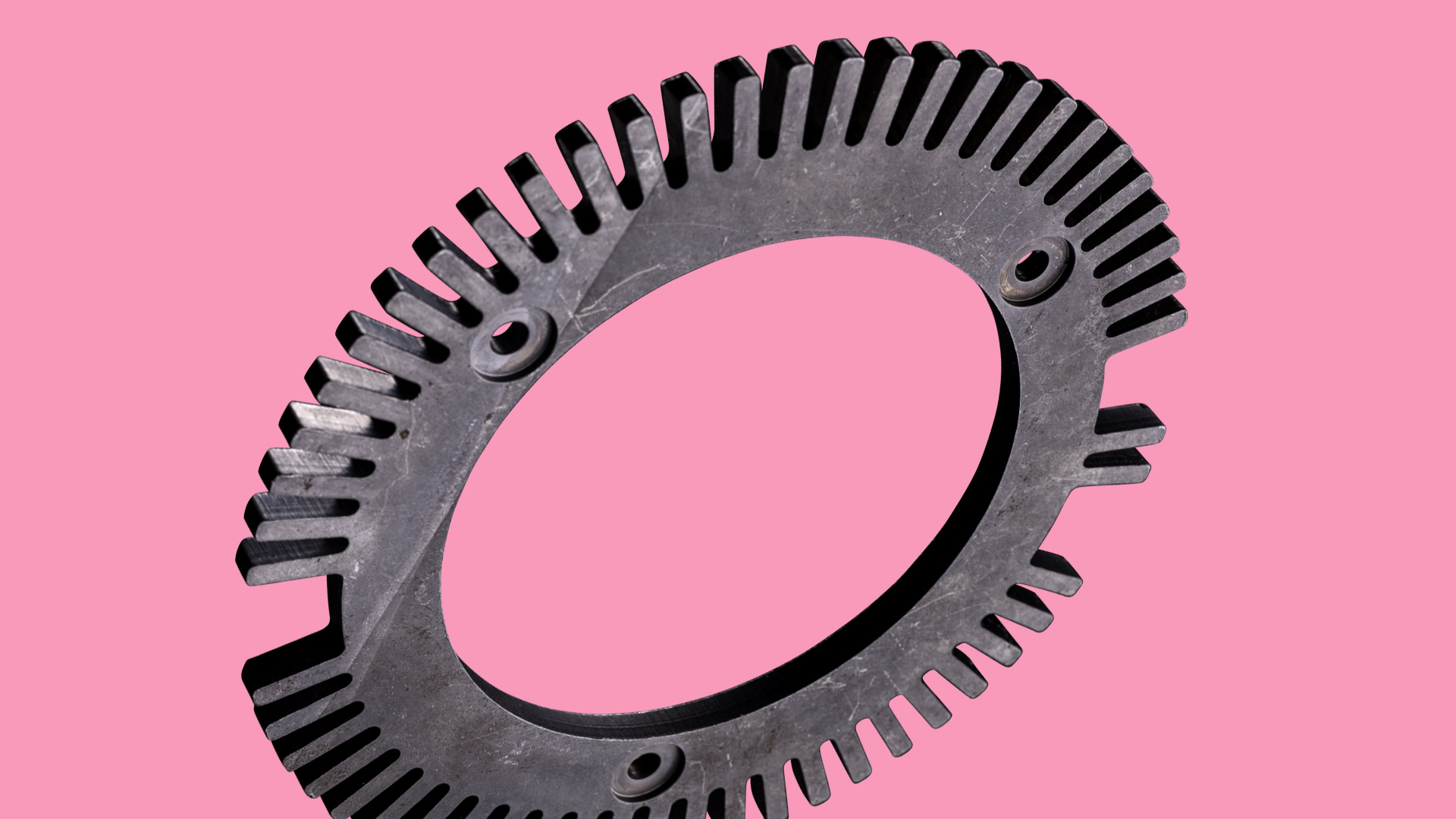

Laser cutting is one of the most advanced and flexible methods for processing stainless steel. The technology uses a concentrated laser beam to cut with unrivaled accuracy, regardless of complexity or level of detail. This makes it ideal for industries with high demands on precision and quality, such as the automotive industry.

Some advantages of laser cutting are

- High precision: With tolerances down to fractions of a millimeter, laser cutting is unbeatable when it comes to precise contours and cuts.

- Flexibility: The method is suitable for both small series and large-scale production, whether it is thin sheets or thicker materials.

- Minimal spillage: The precise process minimizes material consumption and contributes to a more sustainable production.

- Perfect edges: Laser cutting leaves a smooth and clean cut surface, often eliminating the need for post-processing.

Stainless steel as a material

Stainless steel is important in the automotive industry due to its strength, durability and corrosion resistance. At Thor Ahlgren, we process different types of stainless steel to match the specific requirements of each project. Our advanced equipment can handle a variety of thicknesses and sizes, from thin sheets to larger, more robust components.

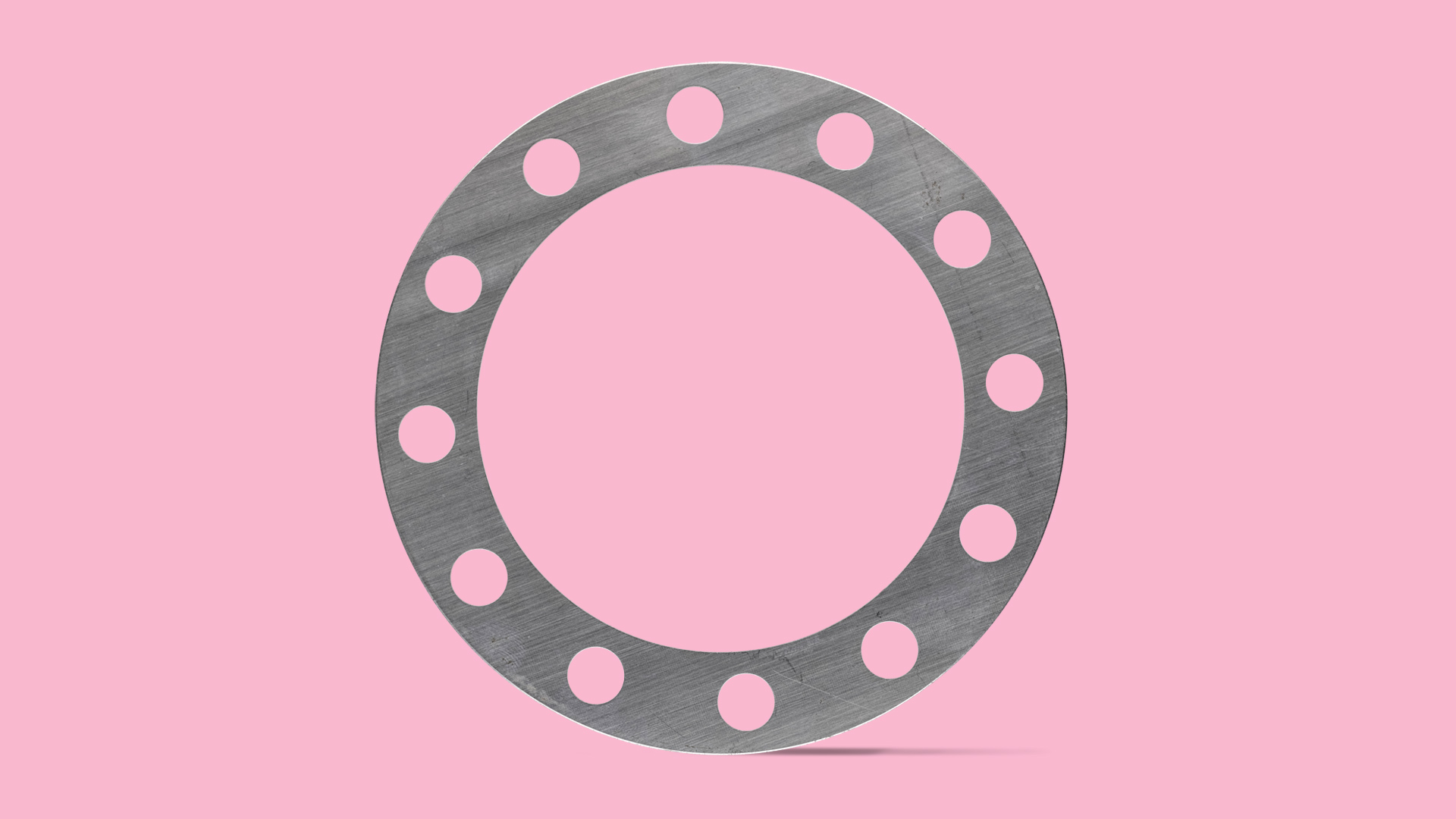

With laser cutting we can create precise details for applications such as

- Vehicle chassis components

- Durable details for vulnerable environments

- Designed components with complex patterns

Our work and certifications

Quality and sustainability are key words in everything we do at Thor Ahlgren. We are certified according to ISO 9001 and IATF 16949, which means that we meet strict requirements for quality and delivery precision. Since 2003, we have also been certified according to ISO 14001, a confirmation of our commitment to the environment.

For us, sustainability is not just about reducing CO2 emissions; it is an integral part of our culture and our daily decisions. We analyse the carbon footprint of our products at item level and work continuously to minimize the environmental impact.

Tradition and technology in symbiosis

Since its inception in 1918, innovation and expertise have been the foundation of our company. Our first laser machine was installed in 2011, and since then we have continuously invested in new equipment. Today, we have several laser machines that handle sheet thicknesses up to 25 mm and maximum sizes of 3000 x 1500 mm. This allows us to offer flexible solutions for both small and large projects.

Despite our technological developments, we never forget our roots. Our people are experts in their fields and see every project as an opportunity to deliver next-level quality. With over 100 years of experience, we're your partner for everything from prototypes to series production.

Your partner in stainless steel laser cutting

Need precise components with tight tolerances? We deliver cuts that meet even the most demanding specifications.

Are you looking for a reliable partner? With our long experience and modern equipment, we can help you from idea to finished product.