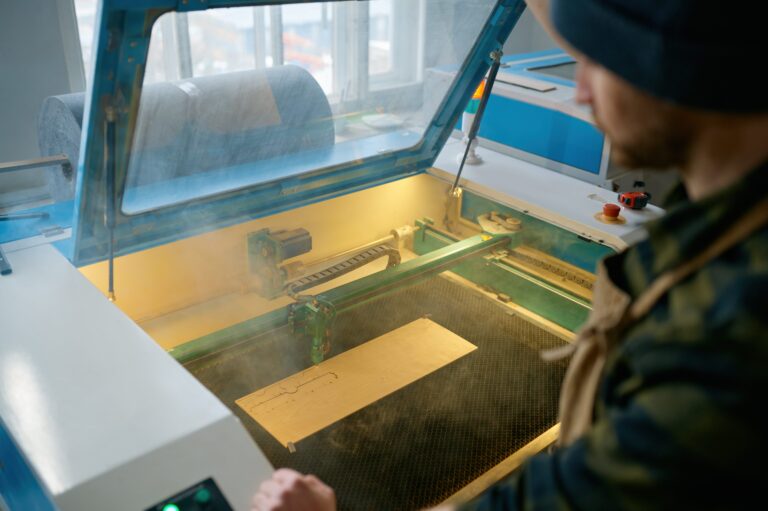

CO₂ laser cutting uses a gas laser with a wavelength around 10.6 µm. This energy is well absorbed by materials such as acrylic, wood, cardboard, textiles and leather, as well as thin metal sheets. The result is narrow cuts and often shiny edges in plastics. The method is relevant when you want high detail, small radii and low heat impact. Compared to mechanical processing, there is no tool wear. Compared to fiber laser, CO₂ is strong in non-metals. Compared to waterjet, it is faster on thinner materials, but requires extraction for flue gases.