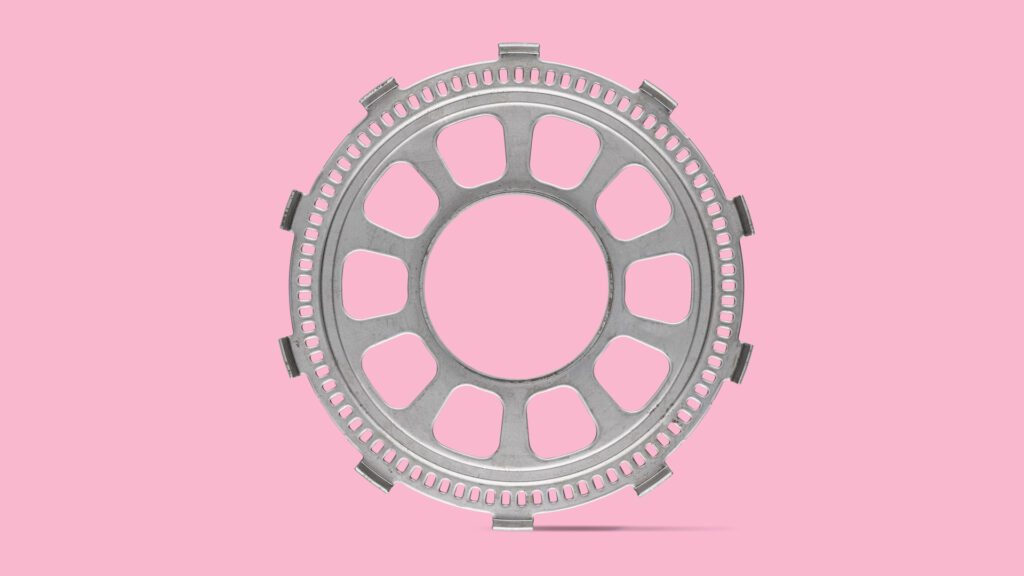

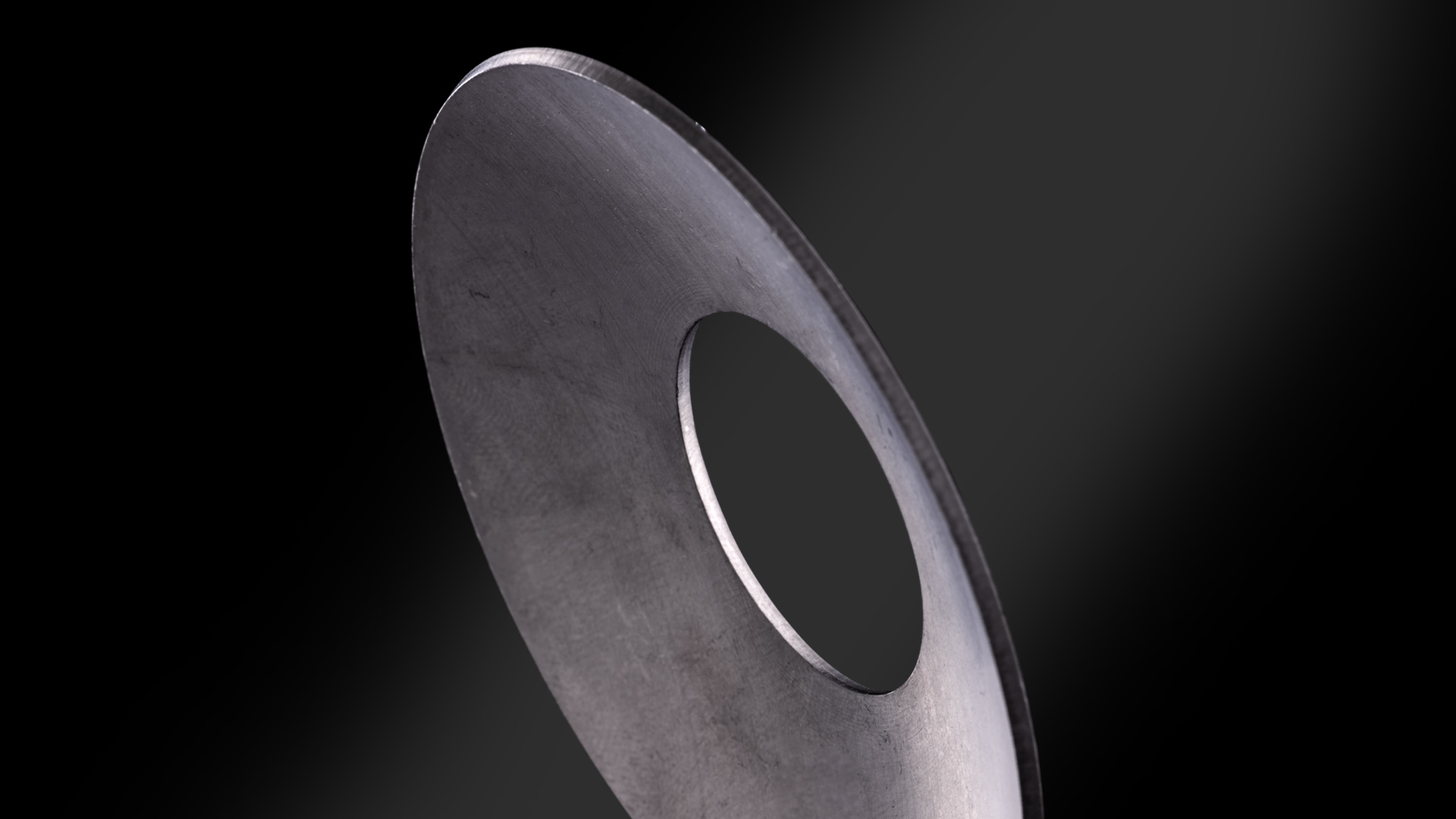

Eccentric pressing

On Thor Ahlgren we have made the hard soft - both in our processing and in our approach. Our motto, "Hard is soft", reflects our approach to metalworking. Despite the strength and robustness of steel, we see its malleability as the key to creating components with high precision and quality.

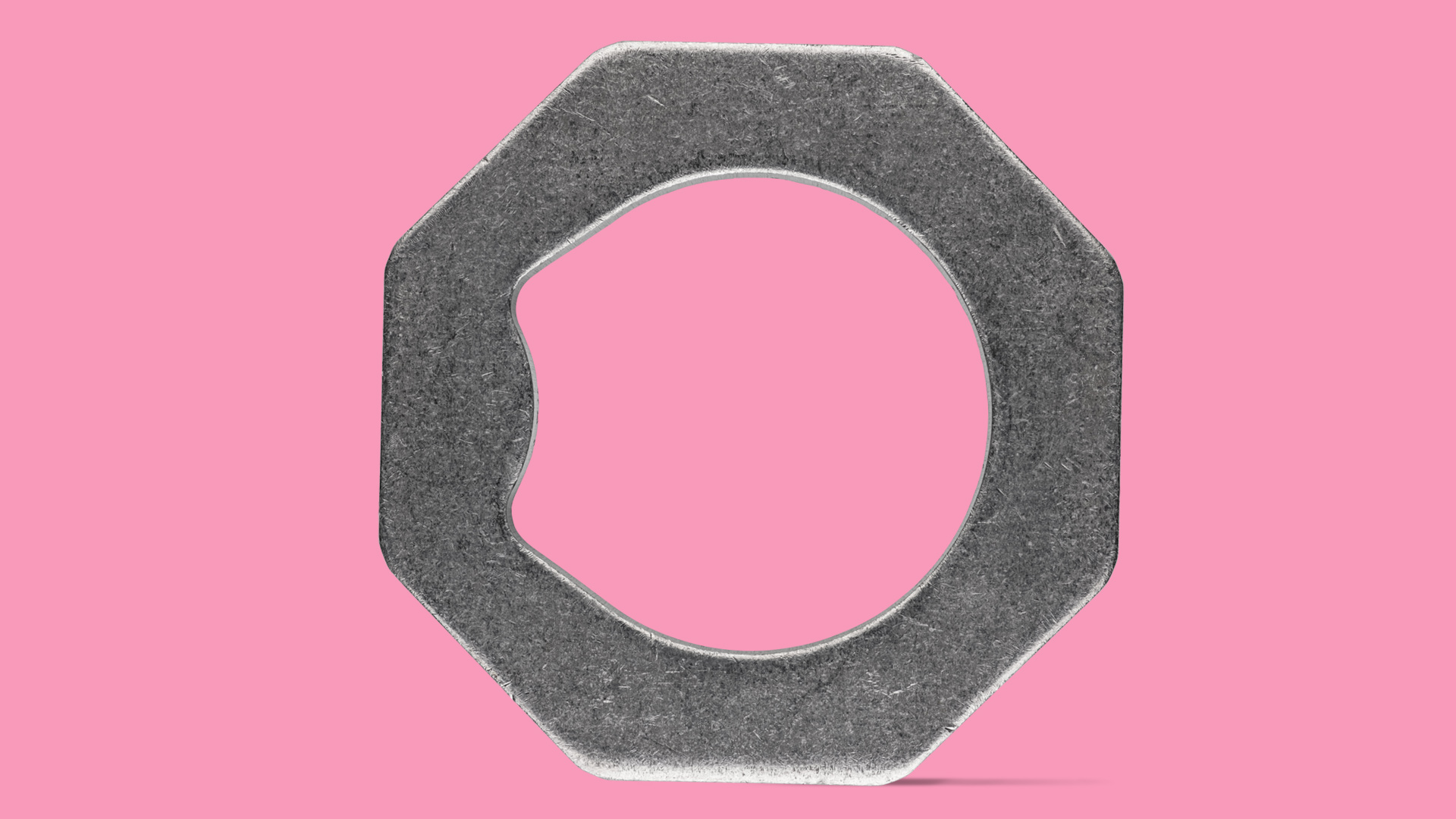

Product characteristics pressing

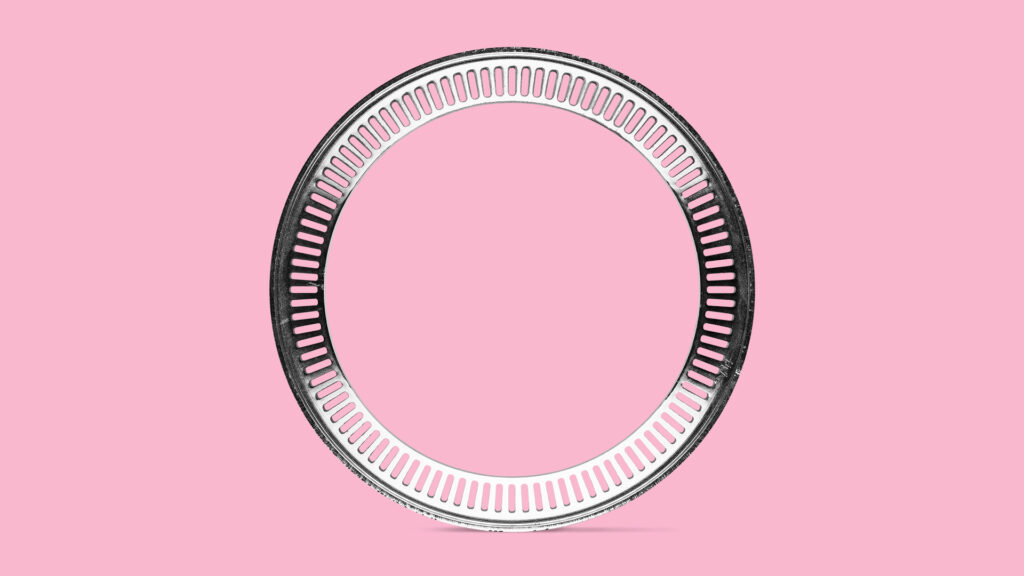

Made of steel, hardenable steel, stainless steel, high strength steel, copper, brass, aluminum

Complicated geometries

High demands on function, tolerances and fit

Use of ultra-high strength steel

Contact us

Contact us and we will help you

Tradition and heritage - A history of craftsmanship

With decades of experience in eccentric pressing, we have built a solid foundation of knowledge and tradition. Our expertise permeates every project we take on, with every step of the process reflecting the precision and skill that only long experience can offer. Combining traditional methods with modern technology, we offer solutions that combine the best of both worlds.

Modern technology for maximum results

We constantly strive to be at the forefront of technological development. Our eccentric presses handle everything from simple to complex geometries, with tolerances that meet the highest industry requirements. With innovative approaches, we help our customers optimize their processes and improve their products - always with precision as our guiding principle.

Four steps to perfect pressed metal

- Needs analysis: We start by understanding your needs. This includes everything from material selection and design to production volume.

- Prototyping: To make sure that everything is perfect before large-scale production starts, we develop prototypes.

- Production of: Our high-tech machines and experienced operators ensure that every part meets your requirements for precision and quality.

- Quality control: Each component is carefully examined before delivery.

Material variety and durability

We pride ourselves on our broad material expertise. From hardenable and stainless steel to copper, brass and aluminum, we can process a variety of materials to meet customers' specific needs. At the same time, our work is deeply rooted in a sustainability mindset. By measuring our CO₂ footprint at item level and constantly working to reduce waste materials, we contribute to a greener future. For us, sustainability is as much a part of our production as our philosophy.

Contact us for a quote

Want to take your project to the next level? Thor Ahlgren is your partner in eccentric pressing. Contact us today for a free consultation or quote. Together we create components with unbeatable precision and quality.